Polycarbonate (PC) properties

Characteristics of PC plastic are its high impact resistance and light transmittance. In addition, this technical plastic is resistant to high temperatures and easy to reshape. The properties of polycarbonate are:

- Highly impact resistant – at least 250 times stronger than glass

- Light transmittance

- Easy to shape

- Suitable for intensive use

- Resistant to high temperatures

- Bendable

- Easy to process

- Option of applying UV and scratch-resistant layer

- Option of ESD-safe coating

Polycarbonate (PC) plastic applications

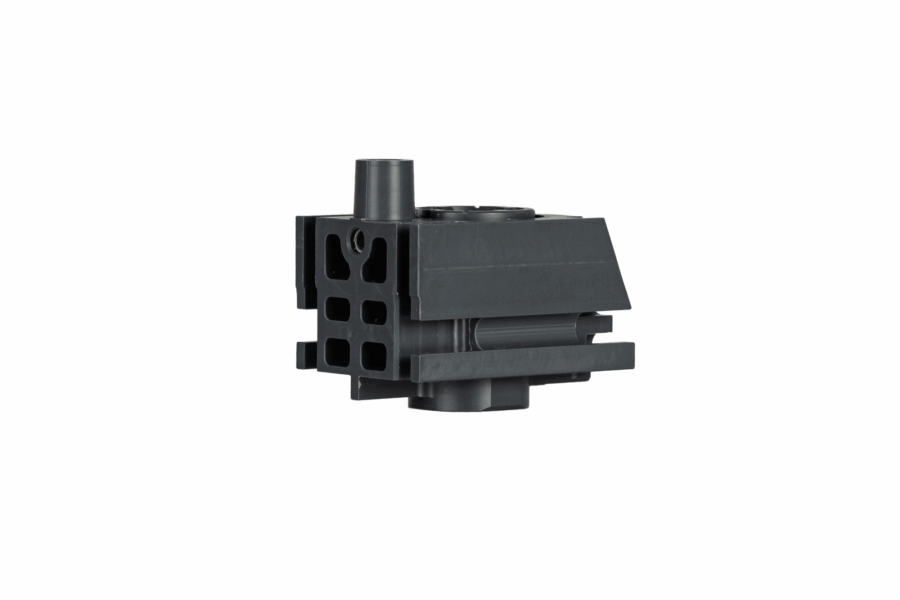

Polycarbonate is the perfect kind of plastic for processes like gluing, shaping and welding. You could even say that working with polycarbonate is a piece of cake for our plastics specialists. PC plastic is especially suitable for intensive usage or when there are high quality or safety standards. BKB Precision has a lot of experience in the realisation of PC plastic applications, including:

- Components for MRI scans

- Assembly of doors and protective covers for medical and food industries

- Other kinds of machine components

Prototypes

BKB Precision has many years of experience in polycarbonate processing for precision parts. Our plastics specialists are without peer in their expertise and skill in accurately shaping, gluing and welding PC plastic.

Our high tech machine park makes it possible to have polycarbonate prototypes made on request. Our aim is to relieve every customer of their concerns through our knowledge of technical plastics.