Machinery BKB Precision

Cutting-Edge Machinery

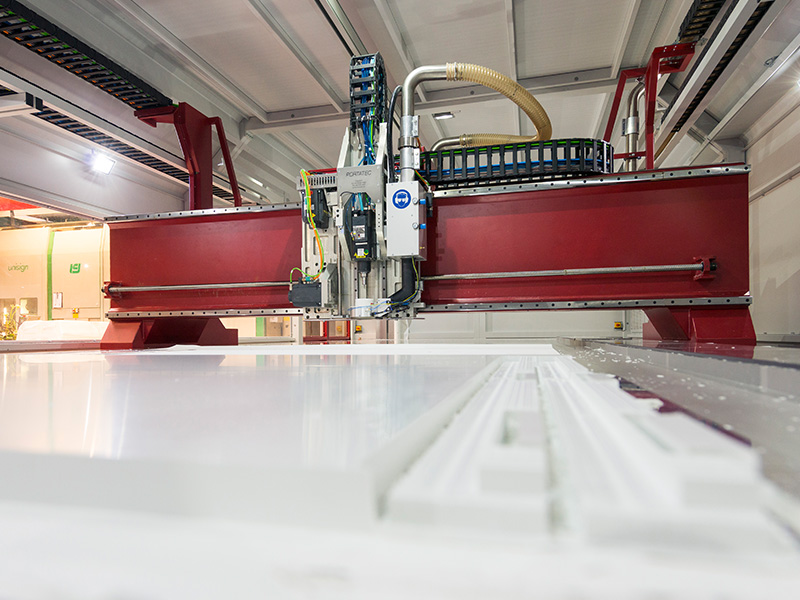

Our recently upgraded machinery forms the backbone of our pursuit of precision in the plastic products we deliver. Through the latest technologies in our machinery, BKB Precision creates an environment where precision and innovation converge.

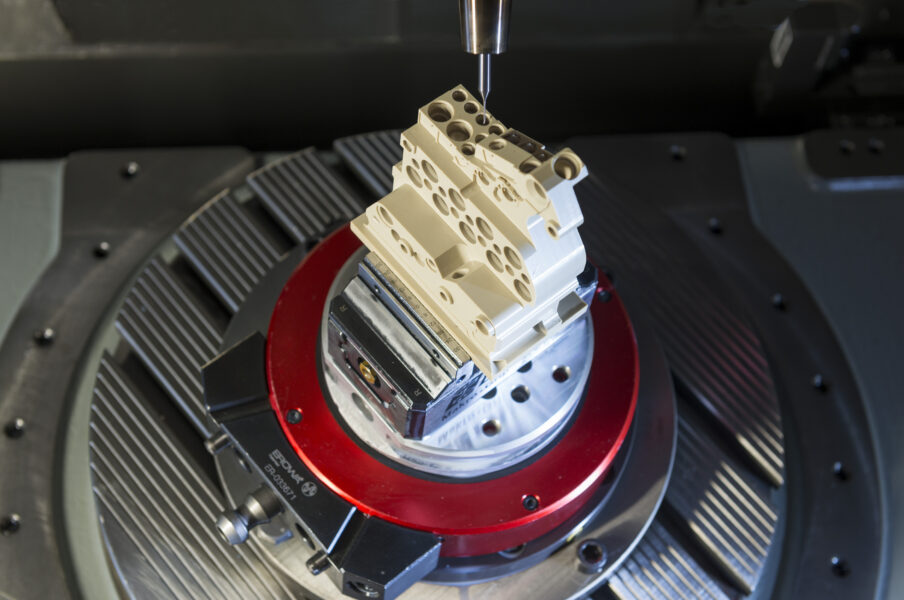

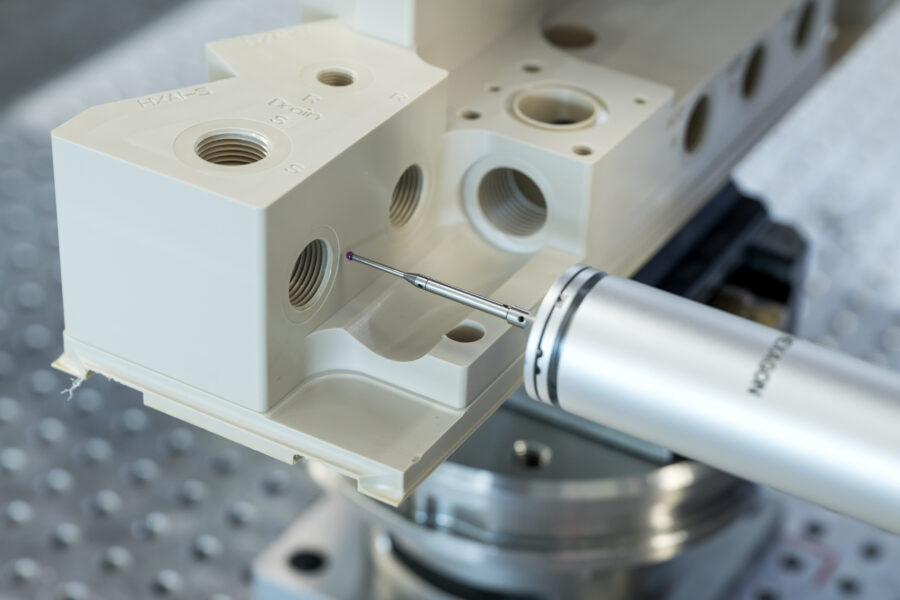

Our state-of-the-art machinery is more than just equipment; it reflects our commitment to progress and high-quality production. From advanced CNC machines to the latest measuring equipment, our entire machinery lineup contributes to a high level of perfection.

Furthermore, we consistently invest in keeping our machinery up to date. Whether acquiring new machines, expanding our toolset, implementing new tools, or investing in emerging technologies, at BKB Precision, we strive to grow and adapt to developments.

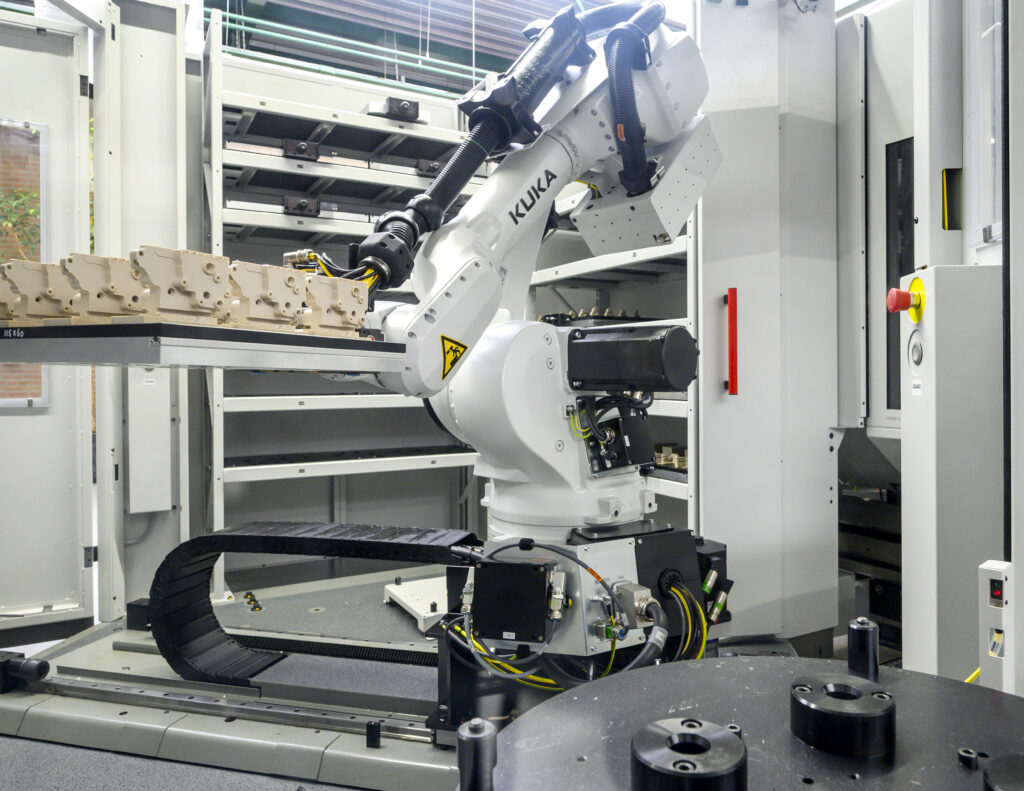

Automation of the Machinery

At BKB Precision, we harness the power of automation to elevate our production process to new heights. With various robots in our machinery lineup, we achieve an uninterrupted production process 24/7. These machines seamlessly collaborate with our CNC machines, enhancing efficiency. Our dedication to innovation and growth allows us to expand BKB Precision’s capabilities, providing our customers with the most complex products.