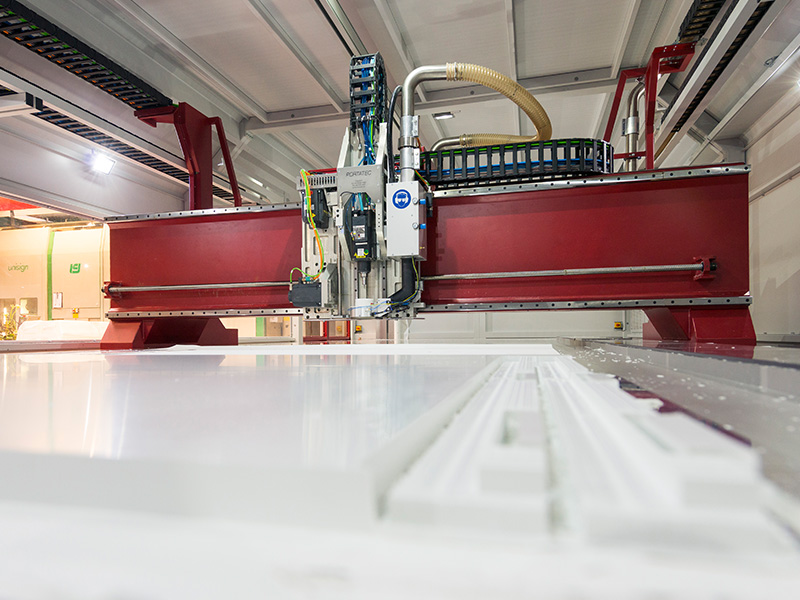

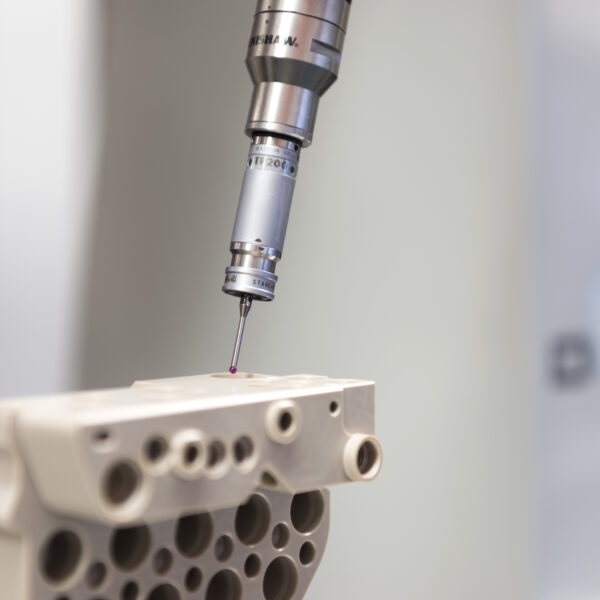

Measurement checks

To carry out checks properly, we have a measuring room with four CMM measuring machines and various measuring instruments. Products pass through the measuring room a number of times during the production process to make sure they are meeting product specifications. In addition, we always carry out final checks. Our measurement specialists are skilled, experienced and will make sure that the checks to be carried out are matched with customer requirements. In addition, we can provide measurement reports and certificates on request.

High QA

We also work with the High QA software package Inspection Manager. This is an innovative quality management system that enables us to largely automate internal production and quality processes. We can use it to do such things as read into 2D drawings and draw up ‘ballooned drawings’ which we can then use to generate measurement lists, including tolerances to be inspected. Once we have the results, we can analyse, monitor and share them with customers and partners.

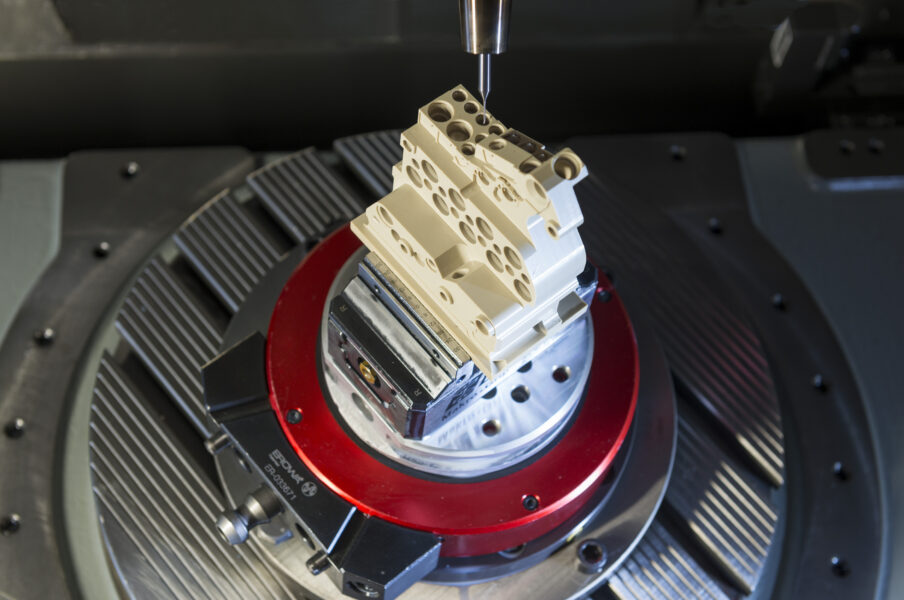

Our measuring machines

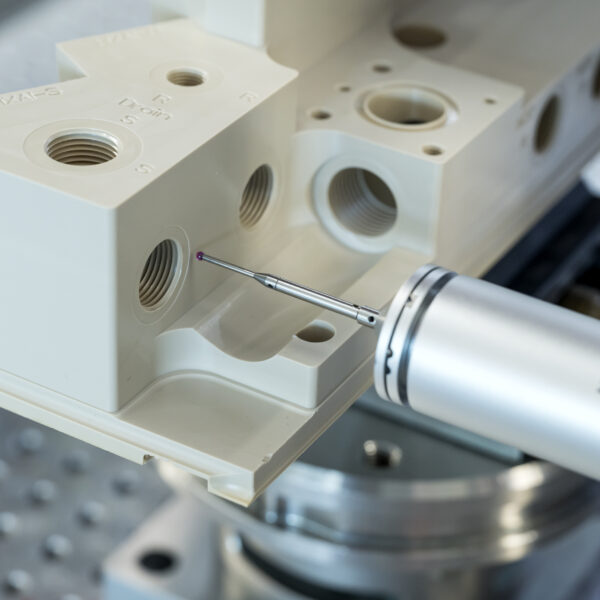

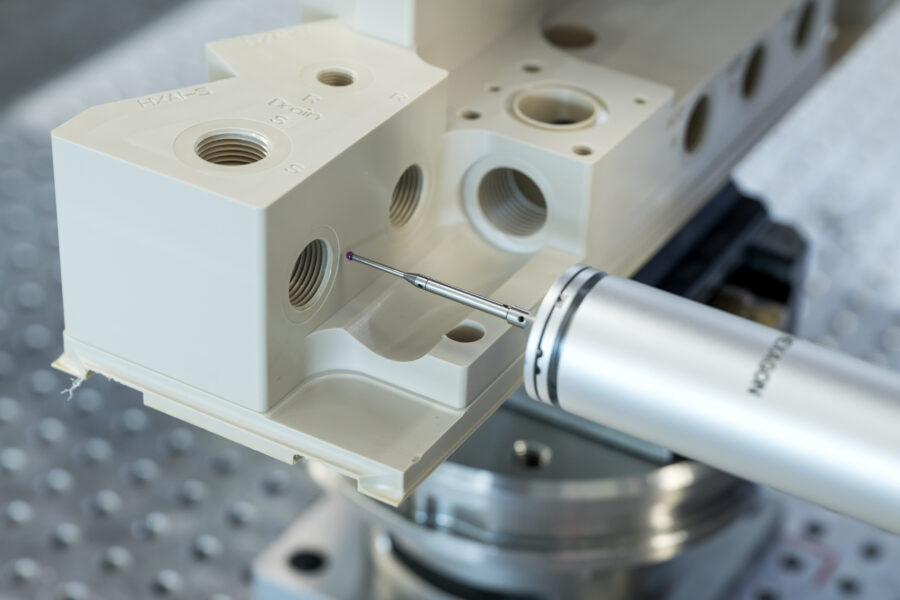

We make the distinction between 3D tactile measuring and optical measuring, although both techniques are extremely accurate. We have one multi-sensor measuring machine which we can use to do both tactile and optical measurements and three 3D measuring machines that do tactile measurements alone.

BKB Precision uses four different measuring machines:

- 1x Optiv Classic 321 GL tp

- 1x CMM/DEA Global Advantage (measurement volume 500mm x 700mm x 500mm)

- 1x CMM/DEA Global Performance (measurement volume 500mm x 500mm x 500mm)

- 1x Global S 07.10.07 Green (measurement volume 700mm x 1000mm x 660mm)

Measuring roughness

We also have a Mitutoyo roughness tester, an instrument which measures surface roughness or smoothness. The surface of a material is scanned with a needle. This needle can detect the smallest instances of roughness and as it moves across the surface, these tiny measurements are recorded.

The parameters are then calculated and, on that basis, a determination is made as to whether the product meets customer requirements or not.