CNC turning-milling combinations

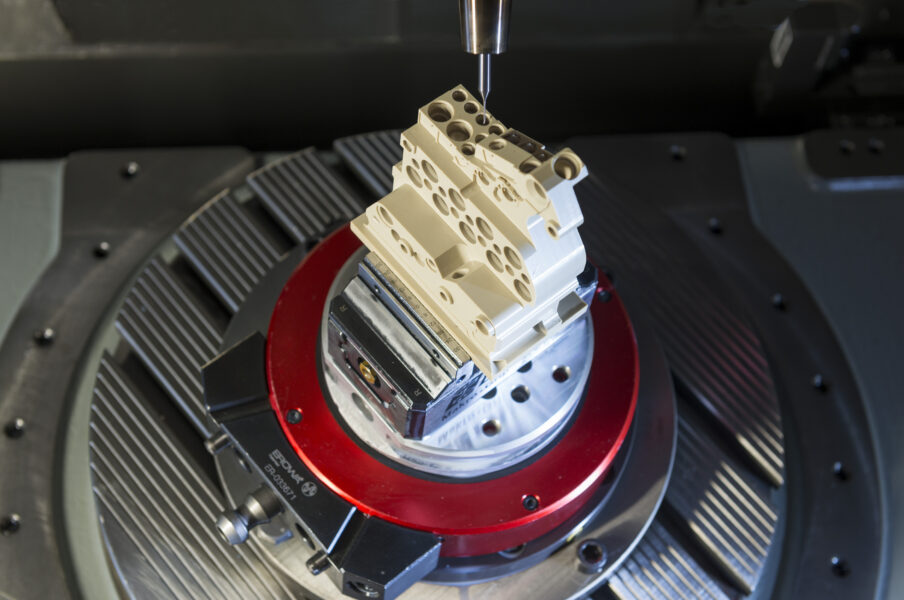

IWe have two Okuma turning-milling combination machines in our climate-controlled production hall:

- 1x Okuma Multus B200

- 1x Okuma Multus B200 II

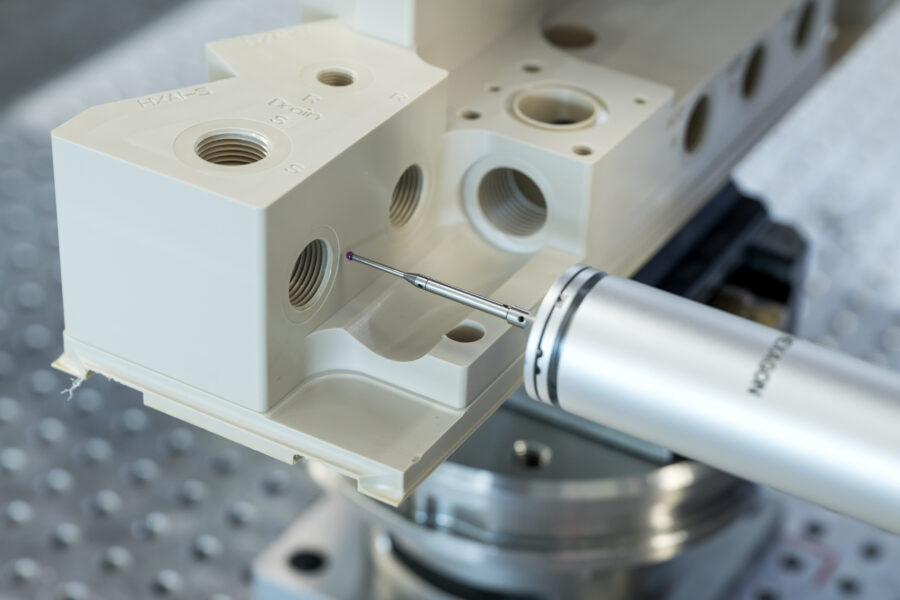

Both turn-mill combinations can turn and mill plastic with an accuracy of up to 3 µm. The Okuma Multus turning-milling machines are stable and guarantee high precision in complex applications. In addition, we keep our production hall at a constant temperature, which means we can continuously produce work at the highest level.

An additional feature of the Okuma Multus B200II is the high-pressure cooling system which allows us to do deep hole drilling: an operation to drill holes deeper than 10x their own diameter. The machine is also equipped with six programmable axes, which means we can do 7-axis simultaneous processing.