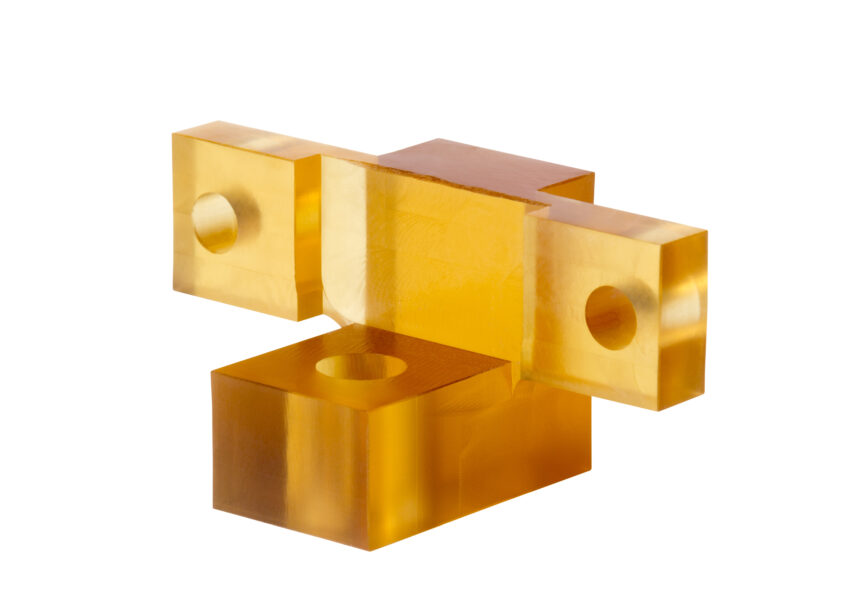

Experience with Polyimide (PI)

We have many years of experience in processing polyimide plastic for various applications. As a result, we know better than anyone what is needed in the field of high-performance plastic processing with polyimide material. If necessary, it is possible to have PI plastic prototypes produced in our state of the art machine park – accurate up to 3μm.

Characteristics of PI plastic

Polyimide can be used at high (and extremely low) temperatures, has no visible melting point and therefore retains its good dimensional stability and mechanical properties. The upper limit for short-term peak temperatures is even up to 400 ° C. Polyimide is good electrically insulating, also flame-extinguishing, resistant to high-energy radiation and has minimal outgassing in vacuum.

- Superior temperature range between -200 ° C up to 260 °;

- Upper limit short-term peak temperatures: 400 ° C;

- No visible melting point;

- Excellent dimensional stability;

- Electrically insulating;

- Flame retardant;

- Resistant to high-energy radiation (e.g .: Gamma or X-rays);

- Minimal outgassing in vacuum;

- High modulus of elasticity;

- Density: 1.35 g / cm3

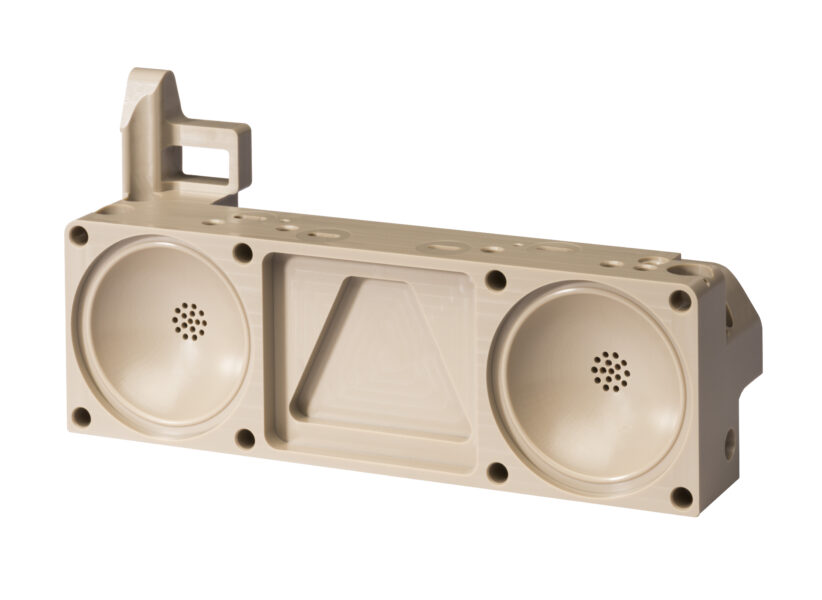

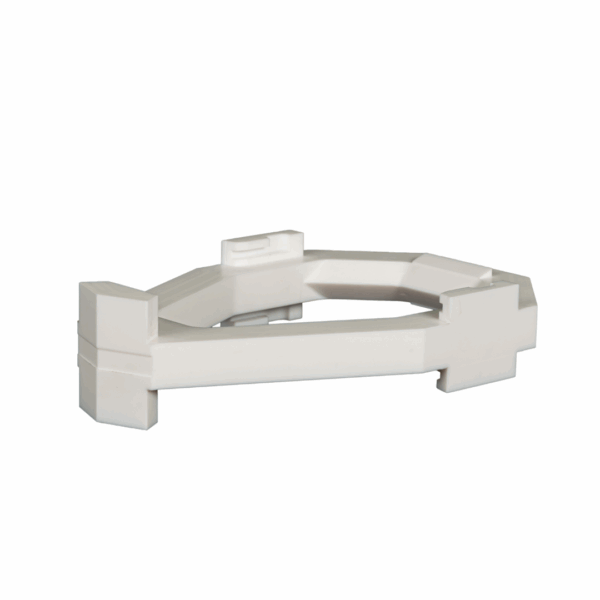

Applications PI plastic

PI plastic is suitable for processing such as plastic cutting, (CNC) machining and gluing. Polyimide is a very high-quality type of plastic and extremely suitable for industries where precision is important. You can think of:

- Slide;

- Bearings Valve seats;

- Electrically insulating parts

- Aerospace parts

- Aviation parts

- Medical parts

BKB Precision specializes in the development and realization of plastic precision parts. Please feel free to contact us if your desired polyimide application is not listed.