PEEK: a short description

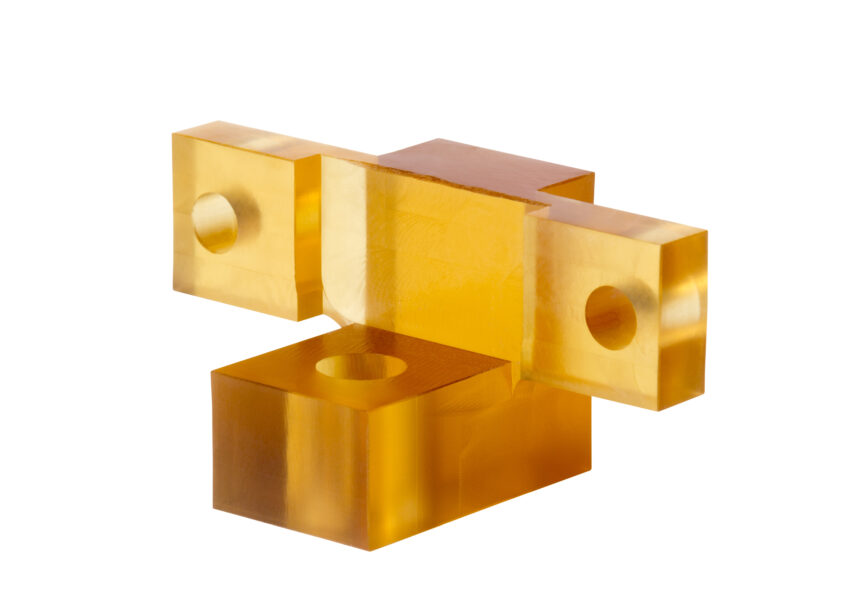

Polyether ether ketone, also called PEEK, has a very high, long-term use temperature (approx. 280 ° C). The plastic is stiff, strong and has an extremely good tensile and bending strength under varying loads.

In addition, PEEK has very good dimensional stability at high temperatures and the material is resistant to chemicals. PEEK is also resistant to high-energy radiation and is self-extinguishing according to UL94. The application of PEEK is very diverse. Think of semiconductor, medical, aerospace, research, etc.

Due to the unique properties of PEEK, these high performance plastics often serve as a replacement for metal components, partly because it is lighter and no corrosion occurs.

PEEK plastic properties

Characteristic of PEEK is that this type of high performance plastic can deliver excellent performance under extreme conditions. Due to the unique properties of PEEK, these high performance plastics often serve as substitutes for metal components. This is because they are lighter in weight and non-corrosive, among other things. The plastic type PEEK (polyether ether ketone) has the following technical properties:

- Very strong, durable material

- Extremely good tensile and flexural strength with varying loads

- Low friction coefficient

- Good dimensional stability at high temperatures up to 300°C

- Excellent chemical resistance

- Excellent hydrolysis resistance

- Resistant to energy-rich radiation

- Self-extinguishing in accordance with UL94

- Low smoke and gas emissions

- Sterilisable

- Density of 1.32 g/cm³

PEEK plastic applications

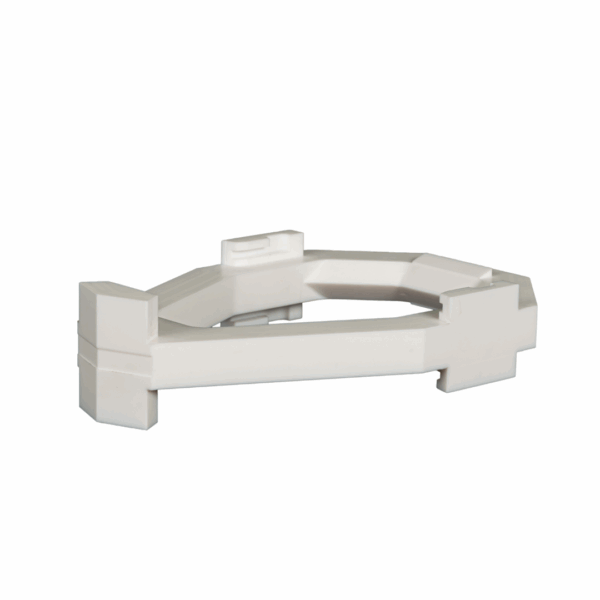

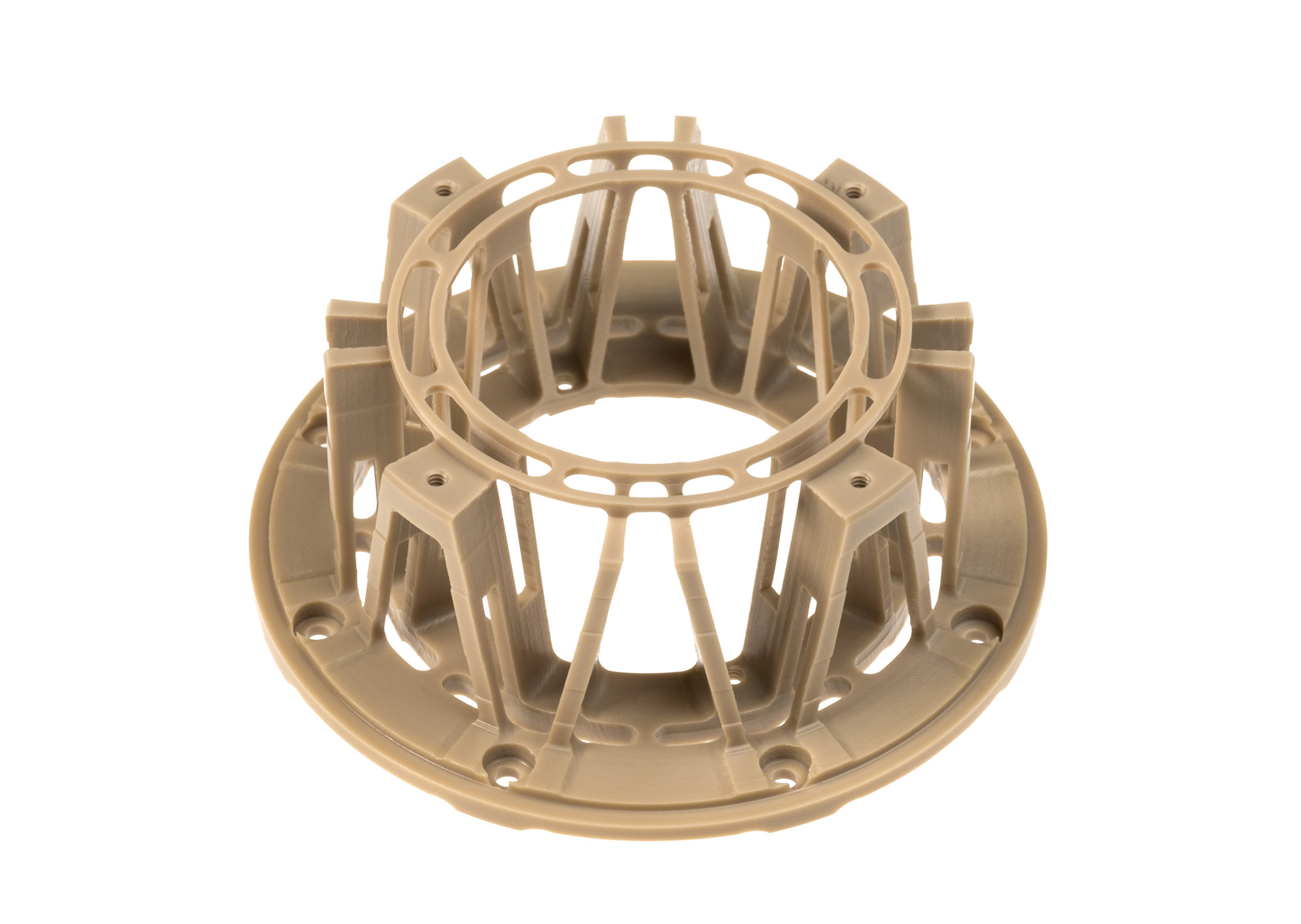

Applications of PEEK are highly diverse, and it is often used for solutions in the fields of semicon, medical, aviation, aerospace, research, etc.

PEEK is highly suitable as a material for components within vacuum environments, as is usual in the semicon industry. The danger of fumigation is low with this type of plastic, which means low levels of particle contamination. BKB Precision has extensive experience in the realisation of complex PEEK plastic applications, including:

- PEEK manifolds

- PEEK ‘Wafer’ equipment

- PEEK plastic tank components

- PEEK micro-electronics

- PEEK lathe components

- PEEK claw plates

- PEEK pipes and fittings

- PEEK lined tanks

- PEEK circuit boards

- PEEK components for filter and distribution equipment

Years of experience

In recent years, BKB Precision has developed strongly in the field of PEEK plastic processing. For the processing of PEEK plastic, we use the most modern CNC machining and milling techniques, including 5-axis simultaneous plastic machining.

We aim to take care of all our customers’ concerns as completely as possible, from design process to end product. We can, for example, have PEEK prototypes produced on request in our advanced machine park.