Environmental Factors and Specific Types of Plastics

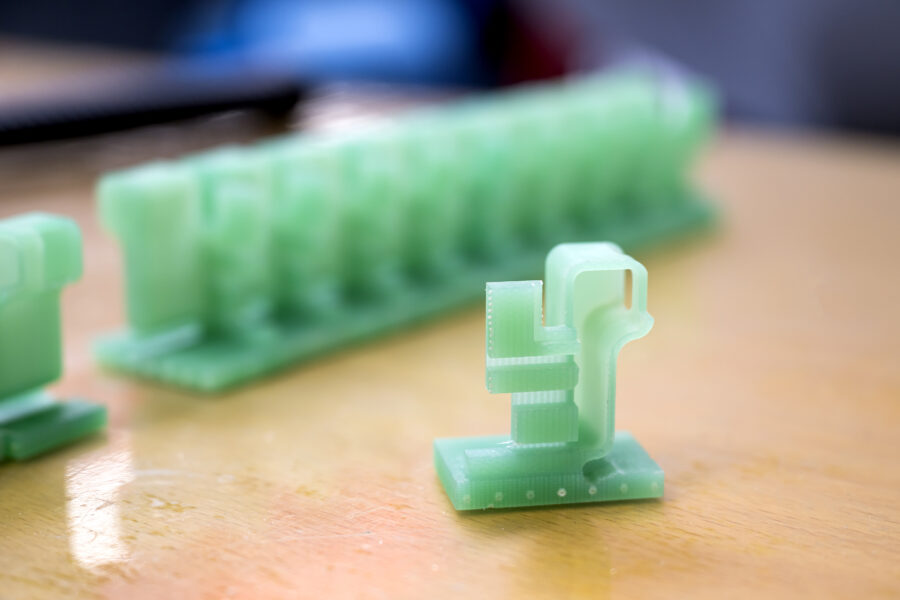

In the world of plastic machining, understanding environmental factors is vital for delivering high-quality products. Different types of plastics respond uniquely to environmental factors, affecting their performance and stability. Below, we discuss some commonly used plastics:

- PEEK: This type of plastic can perform under extreme conditions. It is almost unaffected by external environments, though extremely high humidity over time can reduce its mechanical properties.

- Polycarbonate: Generally, polycarbonate is resistant to temperature fluctuations. However, prolonged exposure to high temperatures can cause this plastic to deform, and long-term exposure to humidity can lead to delamination.

- PE: PE is known for its excellent resistance to moist conditions, making it ideal for outdoor applications. However, the material is sensitive to high temperatures, which can cause softening and deformation.

- POM: Prolonged exposure to UV light can lead to degradation and discoloration of this material.

Choosing the right material for specific environmental conditions is essential to ensure optimal performance in plastic machining. At BKB Precision, we are always open to advising you on the right plastic!

The Role of Temperature in Precision Plastic Machining

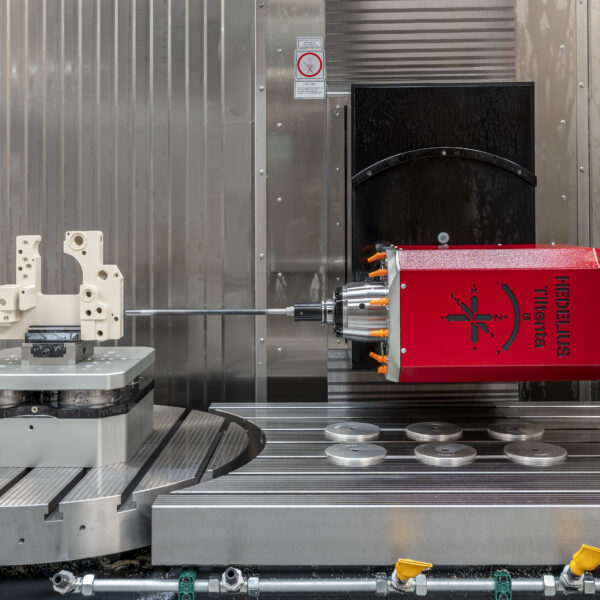

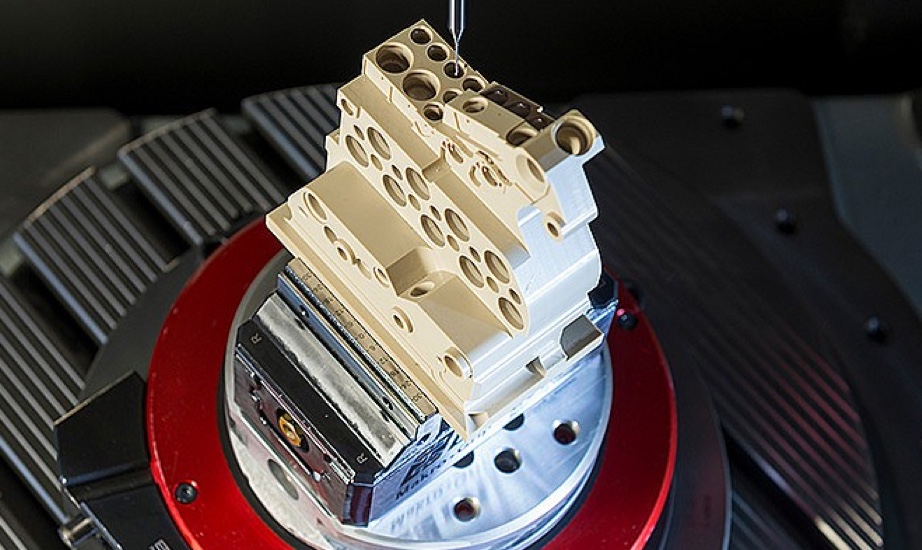

Temperature plays a crucial role in achieving precision in plastic machining. Different temperatures affect the physical properties of plastics, such as expansion, contraction, and thermal deformation. Effective cooling systems, ranging from air and water to special coolants, are essential to prevent overheating and ensure process stability.

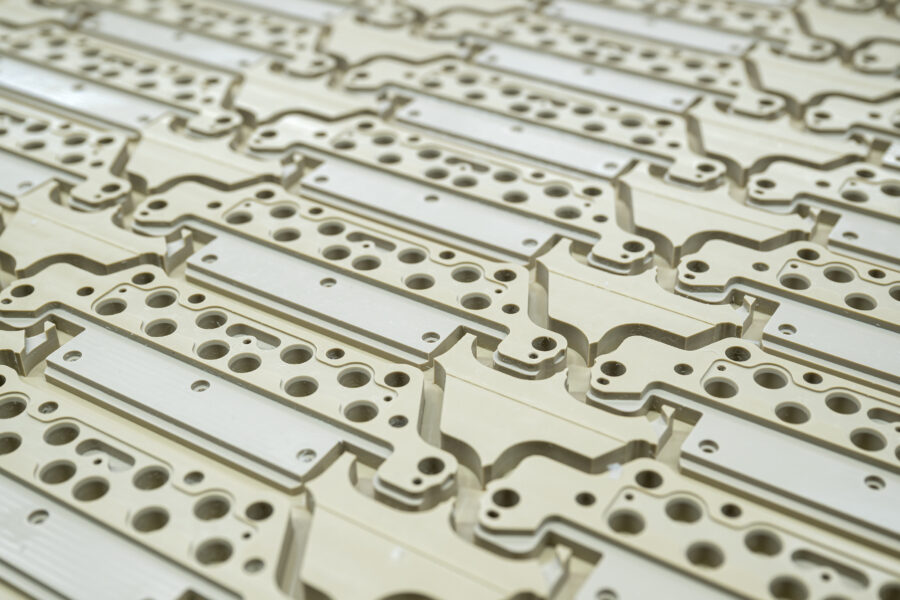

Quality Controls Under Varying Environmental Conditions

Maintaining consistent product quality in plastic machining requires thorough control of environmental conditions, such as temperature and humidity. At BKB Precision, we have a climate-controlled hall where the temperature is kept constant. This minimizes the impact of varying environmental conditions on quality controls. Accurate monitoring and measurement of these factors are essential to detect deviations in time and take corrective actions.