Plastic precision solutions for the medical industry

Reliable, innovative and high-quality plastic CNC solutions for medical applications

Plastics are indispensable in the medical industry today. While requirements for product safety and technical performance are becoming increasingly stringent, plastics offer the ideal balance between functionality, safety and cost efficiency. They play a crucial role in the development of medical devices and instruments. BKB Precision supports this by providing precision components and assemblies that meet the highest medical quality standards.

BKB Precision's expertise in the medical industry

From innovative startups, scale-ups to leading medical machine builders and medical equipment manufacturers - BKB Precision is the reliable partner for high-quality plastic machining in the medical industry. We deliver precision components and assemblies, from prototypes to small and medium-sized series, with quality and functionality always at the center.

At BKB Precision, we believe in long-term cooperation. We go beyond the traditional customer-supplier relationship: we actively think along with you about the manufacturability of your product (DFM), advise on the right choice of material and optimize production processes, so that you can fully focus on your core business.

As a build-to-print+ partner, we ensure that your product is not only technically and economically optimal, but also reaches the market quickly and efficiently. By getting in early, we reduce integral costs, accelerate time-to-market and together deliver reliable and innovative solutions that meet the highest quality standards. Contact us and discuss with us all the possibilities for your project.

The importance of strict quality requirements and certifications in the medical industry

In the medical industry, certifications and quality standards are essential to ensure the safety and effectiveness of products, especially when used in life-saving devices. Therefore, with the MDR (Medical Device Directive EU 2017/745), the medical sector places very high demands on the technical properties of plastics.

The plastics we process at BKB Precision are FDA-compliant, tested according to DIN, ISO 10993-1 and USP Class VI, and come with a material certificate. In addition, we are ISO 9001:2015 certified, have received quality certifications from several high-end clients, and maintain a strict quality policy. Also, we work according to the ISO 13485 Standard which allows us to meet these requirements for the customer as well. We can provide you with various reports and certificates demonstrating our compliance with these standards upon request.

Which plastics are suitable for medical applications?

Medical device manufacturers are increasingly choosing plastics for their unique properties and versatility. More than 50% of all materials in medical devices today are plastics.

The most commonly used high-performance plastics in the medical industry are PEEK and PEI. These materials offer:

- Wide temperature range and chemical resistance

- High dimensional stability and low coefficient of expansion

- Compliance with strict medical regulations such as ISO 10993 and USP Class VI

Medical precision in practice

The medical industry places the highest demands on precision and reliability. At Soteria Medical, they appreciate not only our technical expertise, but also our speed and flexibility. “The short lines of communication and fast service play an important role in our cooperation. It ensures that adjustments to products can be implemented more quickly and easily,” said Gerrit Tigelaar, CTO at Soteria Medical.

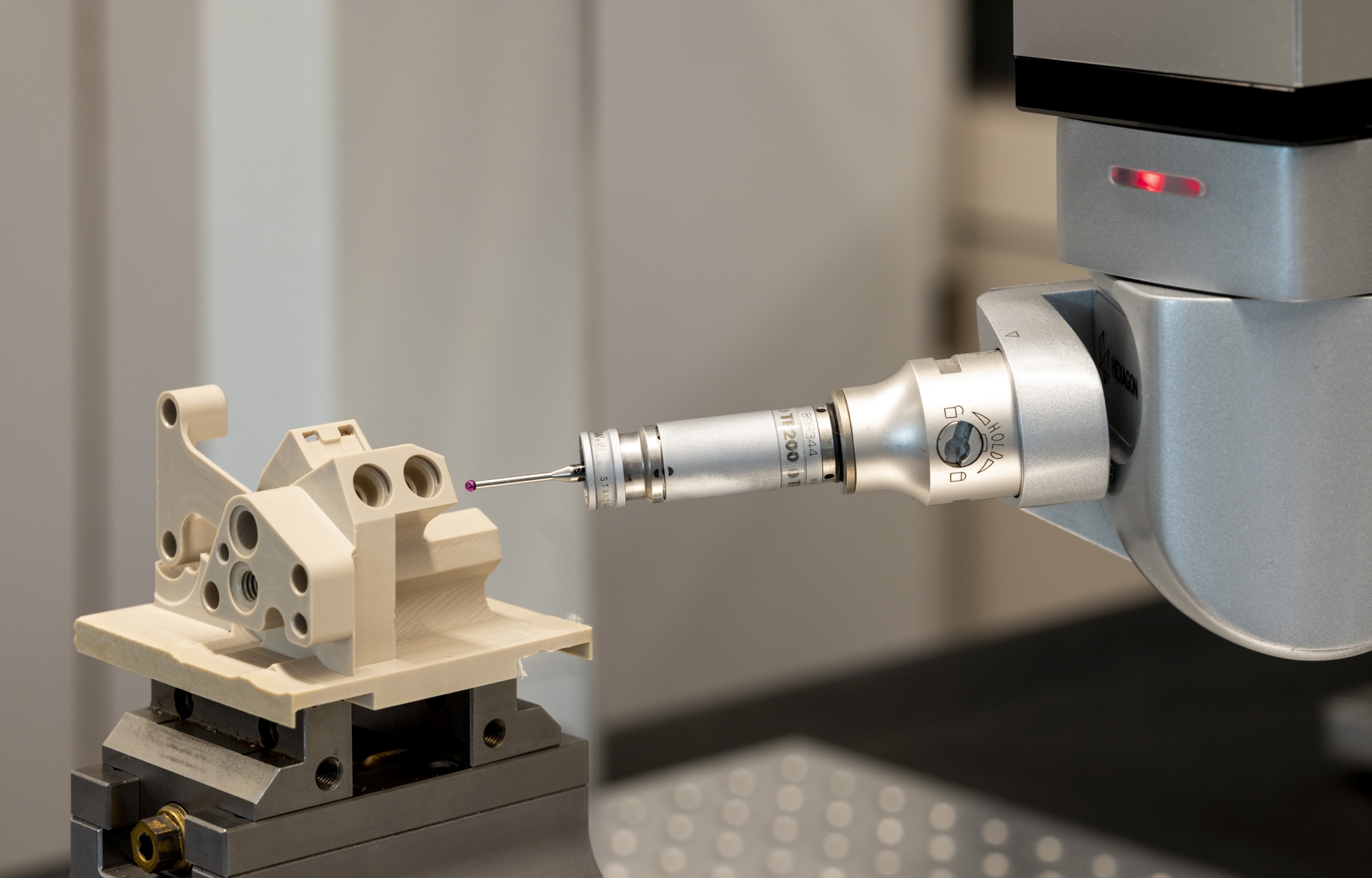

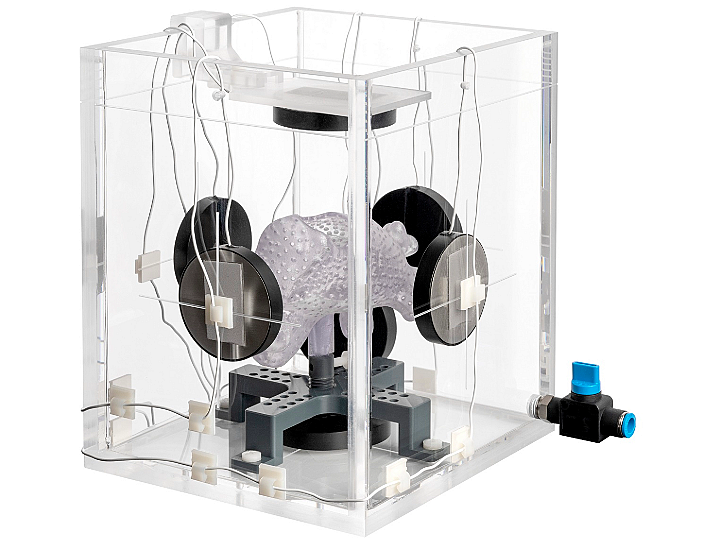

Thanks to our expertise and continuous monitoring of innovations in plastic processing, we can supply high-quality medical components that meet the most stringent requirements. The image next to this text shows another successful project where we supported a customer in the medical sector. Curious about what other customers think of us? Find out via the button below.

Most frequently asked questions for precision solutions for the medical industry

What is a Medical Grade Plastic?

Medical grade plastics are specially designed to meet the high demands of the medical industry. They are biocompatible, chemically resistant and often resistant to sterilization, making them ideal for applications such as implants and surgical instruments.

What certifications must medical plastics meet?

Medical plastics must meet high quality standards. Consider ISO 10993 (safe for human contact), USP Class VI (suitable for medical and pharmaceutical applications) and FDA approval for use in medical devices.

Why is quality control so important in the medical industry?

In the medical industry, a small production error can have major consequences. Therefore, strict quality controls are essential to ensure that medical devices are safe and reliable. Meeting strict certifications and testing procedures minimizes the risk of defects and ensures patient safety.

Can BKB Precision also develop prototypes for medical applications?

Yes, we specialize in developing precision prototypes for the medical sector. As a build-to-print+ partner, we actively participate in the design and development process and ensure the best balance between functionality, manufacturability and material selection.

What are the advantages of plastics over metals in medical applications?

Plastics offer significant advantages over metals in medical applications, such as lighter weight, corrosion resistance, and improved sterilization properties. In addition, plastics can be more easily formed and machined into complex shapes, making them ideal for medical components such as implants and instruments. Also, certain plastics offer high biocompatibility, which is essential for safety and long-term use in the human body.

Can you provide material certificates and test documentation?

Yes, we provide all necessary material certificates and test documentation in line with standards such as ISO 13485 and FDA approvals. So you will always have the right proof of the quality of the materials we supply.

More information about plastic components in the medical industry?

Are you curious about the possibilities at BKB Precision or do you have questions about plastic components and assemblies in the medical industry? Feel free to contact us. You can do so by phone at +31 (0)40 267 01 01 or by filling out the contact form. We will deal with your question as soon as possible.