The emergence of high-tech plastics (PEEK, PPS)

An important development we expect in the coming year is the increasing use of high-tech plastics.

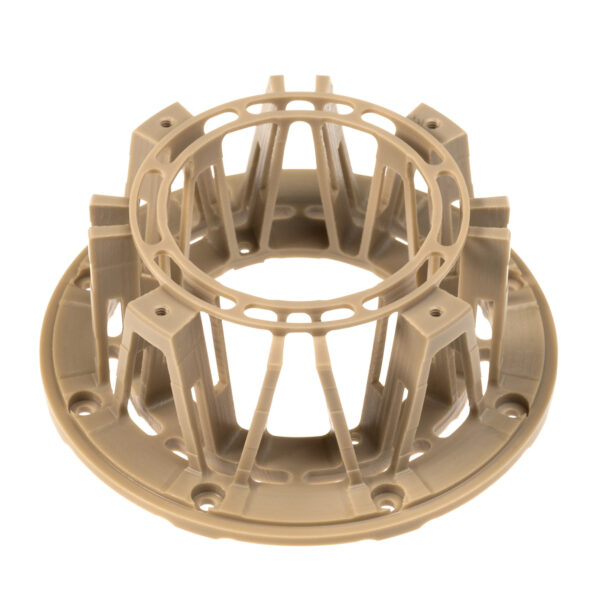

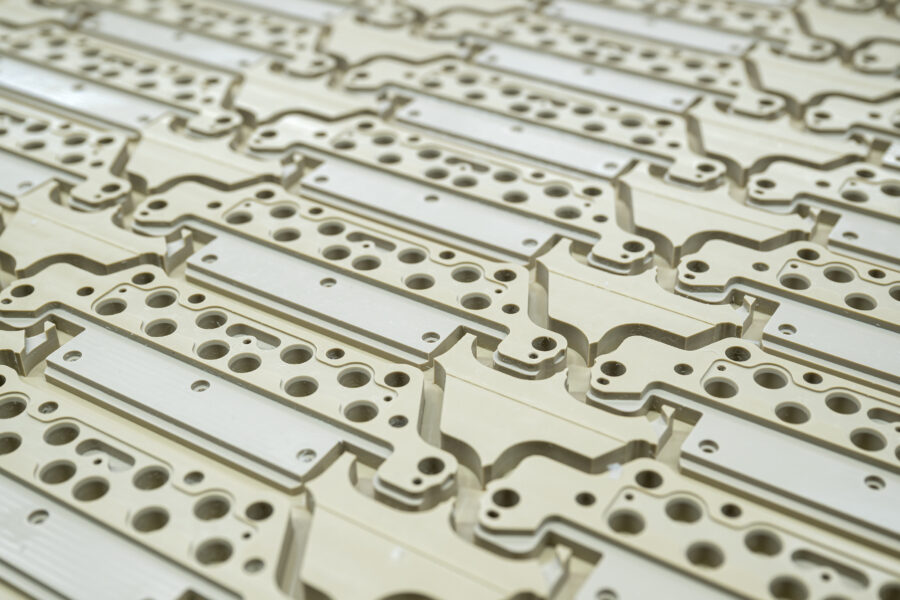

The popularity of PEEK, for example, has already increased considerably in the past year due to its high quality and versatility. This plastic, also called polyetheretherketone, is eminently suitable for precise processing, even at temperatures between 250-300 degrees Celsius. It is also very strong and wear-resistant, making the material durable and easy to use. PEEK plastic is suitable for a wide variety of applications and can even replace metal components. Partly due to its low specific weight, it has many advantages over metal. We expect the use of PEEK to see a considerable increase over the coming period.

Polyphenylene sulphide (PPS) is also expected to see rapid growth in the coming years, driven by an increasing use of this thermoplastic in the aerospace, defence and automotive industries. The extremely hard PPS is flame retardant and resistant to high-energy radiation, as well as being suitable for direct contact with food. Due to its low moisture absorption, it has good hydrolysis and steam resistance and can therefore be sterilized. With the addition of lubrication, it is also highly suitable for sliding applications.

Using plastic for a sustainable circular economy

Something else we will see more in the coming year is the plastics industry actively working towards achieving a circular economy. The demand for waste separation, sorting and recycling is increasing and this creates opportunities for the manufacturers of machine parts.

The plastics industry already makes major contributions when it comes to technical solutions and we only expect this to increase in the future. In addition, there are many initiatives in the field of producing and storing sustainable energy. The solutions developed would not be possible to realise without the favourable material properties of plastics, such as chemical resistance and insulating capacity.

In the ‘New Energy’ market, BKB Precision is already a preferred supplier for many start-ups and scale-ups working in this field.

Industry 4.0

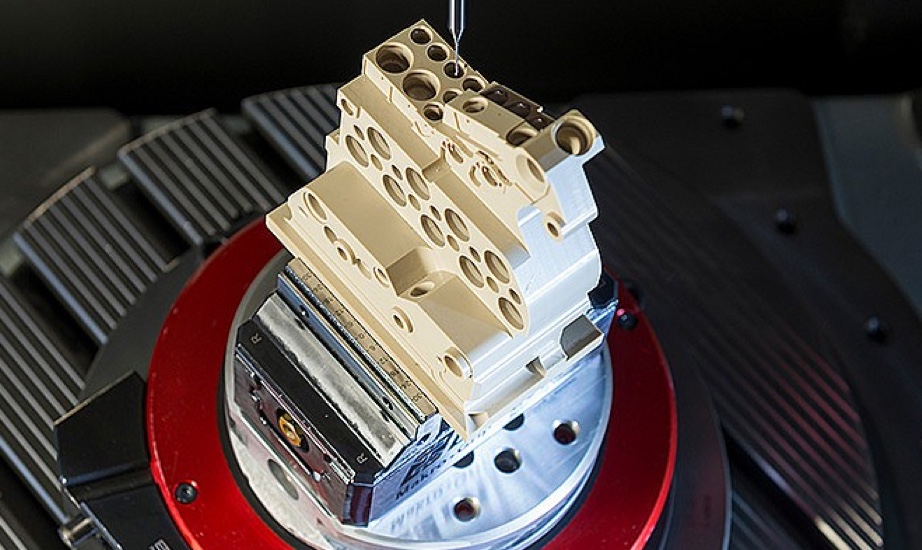

One last important development we would like to discuss is the emergence of Industry 4.0. The rise of the Internet of Things and other technological developments mean that every part of the plastics industry can communicate with and be connected with every other.

This means that we as processors and producers can respond even better to customer demand, accelerate production, and make the process more flexible. BKB Precision is at the forefront of these developments and has been working with Supply Chain Collaboration Platforms for some time.

Trends

We have also identified a number of trends. These are as follows:

- Between 2020 and 2027, the global market for thermoplastics is expected to grow at a rate of 5.2% per year. The growth figure for PEEK is expected to be more than 7% per year. This is chiefly due to the many benefits of thermoplastics and its increasing acceptance in various branches of industry.

- The industry is driven mainly by the increasing demand for lightweight materials such as plastics and the growing number of end-user applications.

- In addition, important factors driving the growth of the thermoplastics market are a growing acceptance of thermoplastics in the automotive industry, growing demand for automobiles, and growing demand for recyclable and fast curable materials. Composites which can replace metals are also increasingly penetrating the market. This specific sector does not focus on high-mix, low-volume, high-complexity buyers, given the large series. For BKB Precision, this is therefore not a market in which we actively operate, but we do follow developments and learn where necessary.

- The thermoplastics market is looking good with opportunities in a variety of applications, such as powertrain systems, electrics and electronics, chassis systems, and interior, exterior and underbody systems. The specific requirements of the automotive sector, such as lightweight and durable materials, will drive future demand for thermoplastics.

- Polyphenylene sulphide (PPS) is expected to experience the fastest growth in the coming years (8.8% per annum up to 2025), driven by an increased use of thermoplastic composites in the aerospace, defence and automotive industries.

Want to know more about what is possible with plastic processing? Then please contact us with no obligation. We would be delighted to talk to you.

Sources:

https://ihsmarkit.com/products/chemical-high-performance-thermoplastics-scup.html

https://blog.technavio.com/blog/aromatic-ketone-polymers-leading-resurgence-thermoplastics

Need advice or more information?