Looking back: trends and developments in plastic machining in 2025

In 2025, it became clear that the plastic machining market was entering a phase of maturity. This was evident from, among other things, the arrival of various new entrants and the growth of specialisms. However, innovations in the field of bonding, the continued development from metal to plastic, digitization, and sustainability also ensured that existing companies in this market continued to innovate. This resulted in more opportunities with regard to plastic processing. These trends are explained in more detail in our blog article on the trends and developments of 2025 and form an important basis for developments towards 2026.

Trend 1: Specialization & extra value-added services

By 2026, the role of plastic machining companies will shift even further and more frequently from supplier to chain partner. Customers expect not only accurately milled or turned parts, but complete solutions that go beyond the machining process alone.

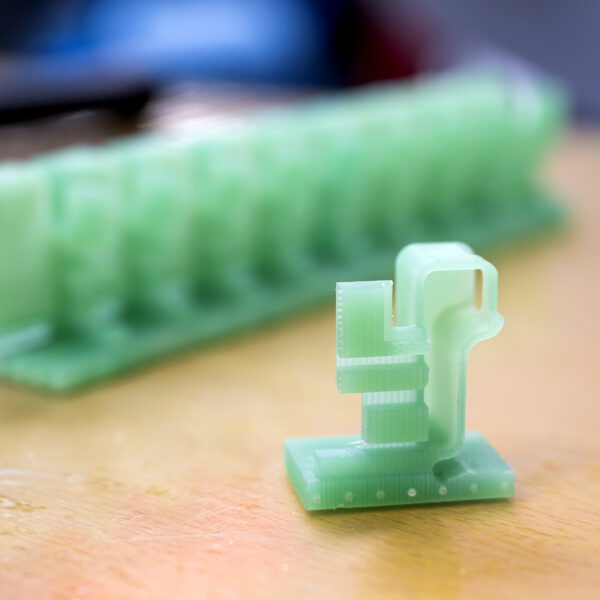

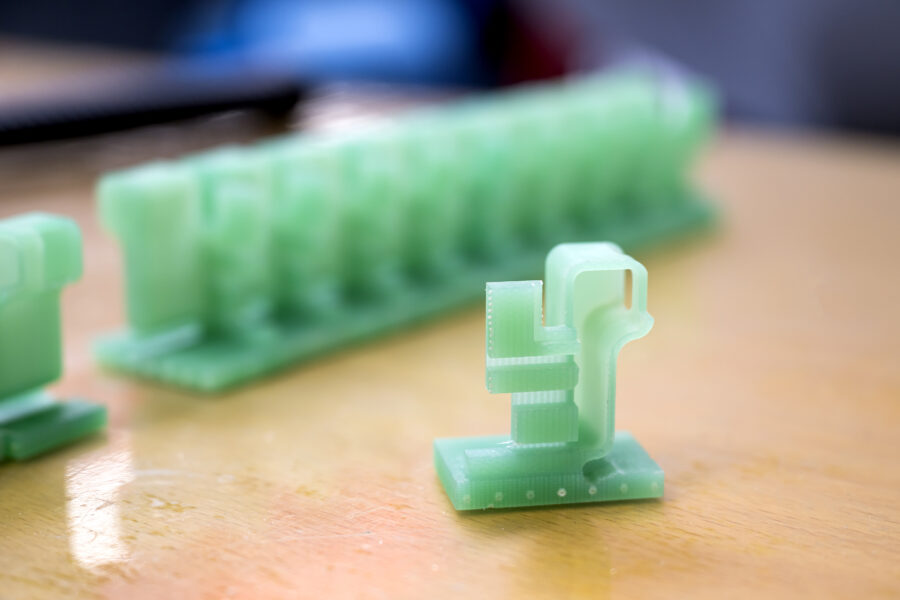

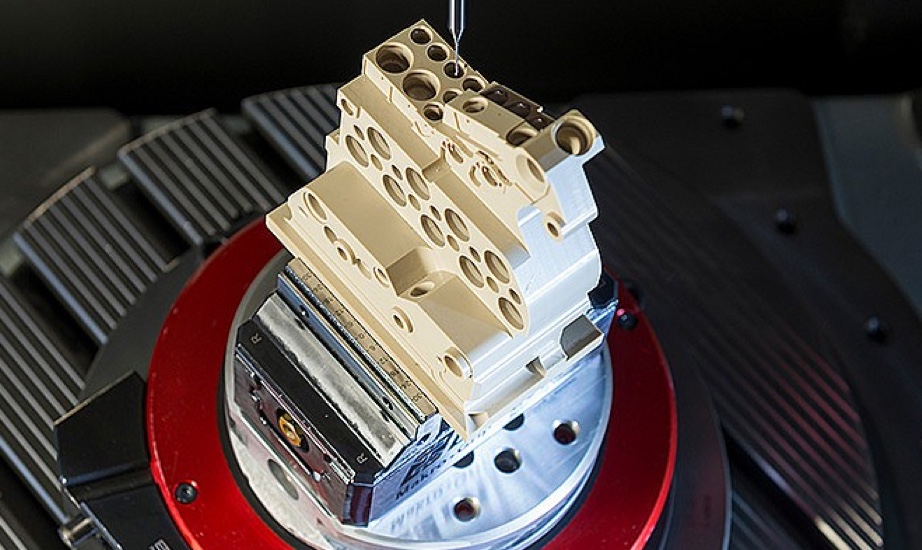

The integration of bonding, assembly, and other preparatory processes within a single chain is becoming increasingly common. At the same time, there is also increasing demand for hybrid production methods, in which machining is combined with additive manufacturing, for example. This is easier said than done. Discover how we at BKB Precision recently achieved this with extreme precision for a high-end customer in the high-tech industry.

Trend 2: Increased use of high-performance plastics in the defense industry

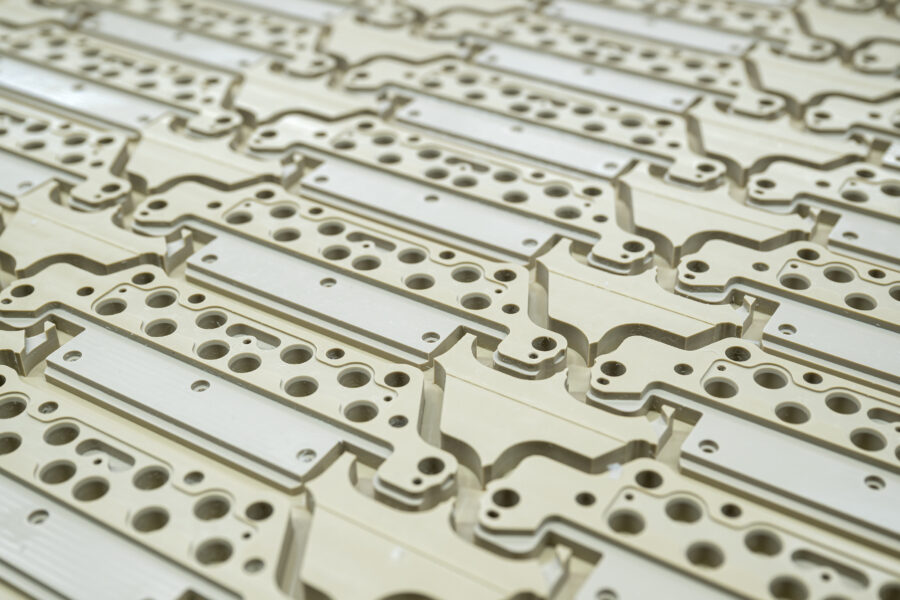

By 2026, the defense industry will have developed into an important growth market for high-performance plastics. Due to stricter requirements in terms of weight, durability, and functionality, metal components are increasingly being replaced by high-quality plastics such as PEEK and PEI. These materials not only offer technical advantages, but also contribute to design freedom and functional integration.

For plastics machining companies, this means an increasing need for in-depth material expertise, process reliability, and quality assurance in order to meet the high demands of this sector.

Trend 3: AI and smart machining are in their infancy

Although AI and smart machining will not yet be commonplace in the plastics machining market in 2026, they do mark the beginning of a fundamental change. Current applications focus primarily on insight and support, but already demonstrate the potential of this technology for process control and quality.

As systems mature, AI-driven processes will play an increasingly important role in efficient and scalable production. The use of AI is also increasing creativity in the machining process. Early adoption and experimentation are therefore an important step towards future-proof machining.

Trend 4: Sustainability and circular machining

Sustainability and circular machining will continue to play a role in 2026. Within the market, this will certainly remain a key pillar in the coming years, with increasing demand for demonstrable sustainability, requiring organizations to be able to substantiate their CO₂ impact per product and process. This development makes sustainability a distinguishing factor and a strategic competitive advantage.

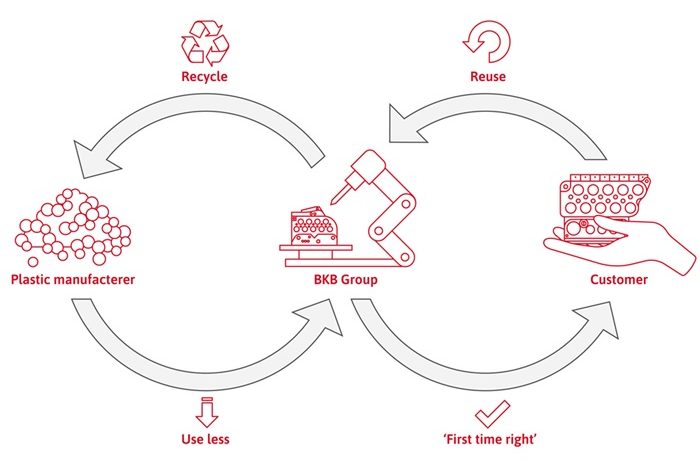

Circular thinking is no longer limited to the choice of materials, but extends across the entire production process. The structural reuse of plastic waste streams, investment in energy-efficient machines, and the use of minimal or dry machining are important developments in this regard.

At BKB Precision, we have also been working on this for a number of years and will be publishing our third sustainability report in Q2, which will detail exactly where we stand on this issue. It will also outline the steps we still need to take and will be taking to become even more sustainable.

In 2025, we will also have set up a reuse process for a single customer, but for multiple items, whereby we reassess, repair, and clean the items we produce for a new round of use.

Trend 5: International expansion and scalability

International diversification will become an increasingly important building block for sustainable growth in 2026. The establishment of a branch in Malaysia is therefore an important step in the international growth strategy of the BKB Precision group. This expansion contributes to risk diversification and increases the agility of the organization.

At the same time, there will be a strong focus on more intensive collaboration within the group in the coming year. By making better use of capacity, knowledge, and resources across the various locations, the different branches within the group will be able to provide their customers with even better support in terms of flexibility, delivery reliability, and scalability. Manufacturing the product where the price-quality ratio is optimal for the customer.

Ready for the future of plastic machining

As we approach 2026, it is becoming clear that success in the plastic machining market requires more than just technical expertise. Sustainability, specialization, smart technology, and international cooperation together form the building blocks for further growth. Would you like to discover how BKB Precision is leveraging these trends to optimize your production processes? Contact us and talk to our specialists.