The growing role of plastics in the semiconductor industry

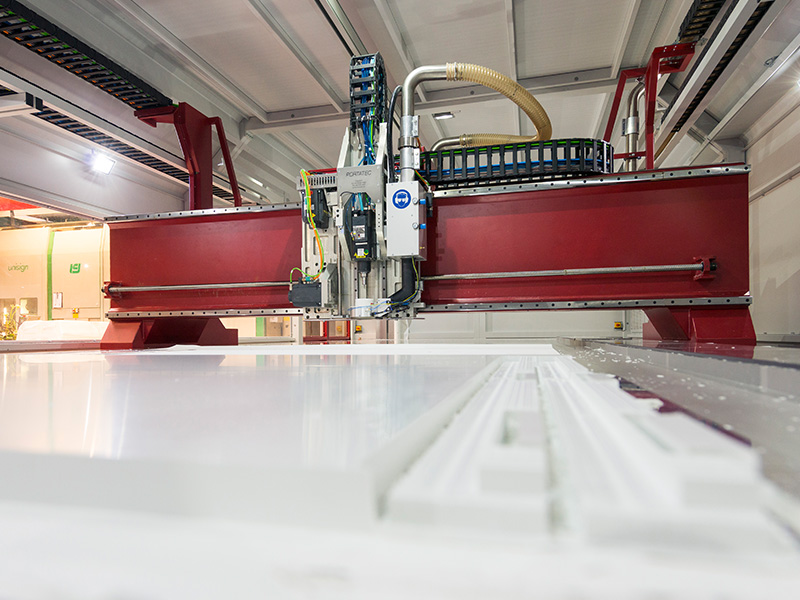

The semiconductor industry is developing rapidly. As products become smaller and more complex, metal components are becoming less and less suitable in terms of weight, workability, and purity. As a result, the preference is increasingly shifting to high-quality plastics. Thanks to their chemical resistance, design freedom, and excellent insulating properties, plastics are an attractive and reliable alternative in critical semiconductor applications.

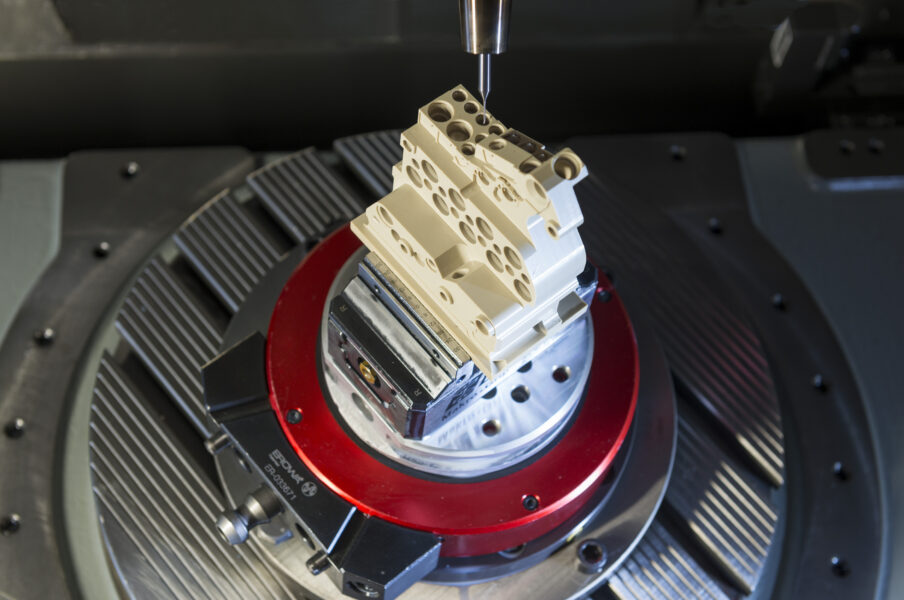

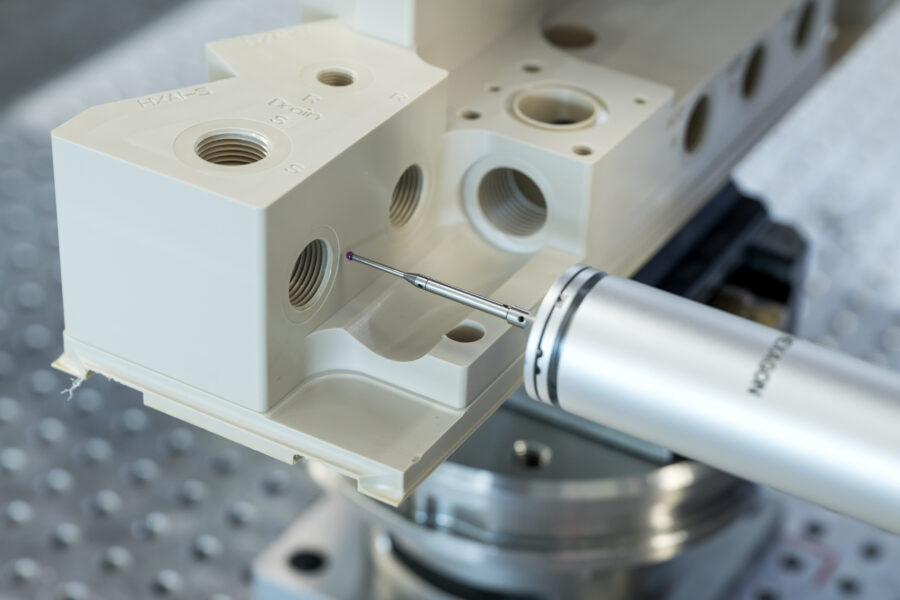

At BKB Precision, we understand what this entails. We machine plastic components with the utmost precision and care, fully in line with the high quality standards of the semiconductor industry.

Which plastics meet the requirements of the semiconductor industry?

Not every plastic meets the high requirements of the semiconductor industry. Materials must be pure, dimensionally stable, chemically resistant, and suitable for use in vacuum and cleanroom environments. In this respect, PEEK is one of the most reliable and most widely used plastics in this sector. Thanks to its combination of mechanical strength, low outgassing, and chemical resistance, it is ideal for precision applications.

Depending on the application, other high-performance plastics may also be suitable. At BKB Precision, we provide daily advice on the right choice of material for each specific issue.

Build-to-print+ for maximum quality and peace of mind

At BKB Precision, we go beyond simply manufacturing according to drawings. As a build-to-print+ partner, we actively support our customers in translating their designs into manufacturable and reproducible end products. Where desired, we contribute ideas about material selection, tolerances, and machining options, and we provide advice to guarantee quality.

Thanks to our extensive experience in the semiconductor industry, we know the technical limits and how to achieve maximum results within these limits. This means we don’t just supply a component, but a complete total solution, including finishing or assembly where desired.

Frequently asked questions in the industry

The semiconductor industry often requires very strict tolerances, ranging from ±0.01 mm to ±0.005 mm, depending on the specific application and component. At BKB Precision, we can meet these tolerances.

Quality assurance is achieved through strict control of material selection, precise production processes, compliance with industry standards, and testing such as outgassing analyses and chemical resistance tests. Discover how BKB Precision guarantees this quality on our quality page.

Naast verspanen kunnen kunststofcomponenten worden onderworpen aan nabewerkingen zoals assemblage, reiniging in een cleanroom, het aanbrengen van coatings voor extra bescherming en nog vele andere technieken.

In addition to machining, plastic components can undergo post-machining such as assembly, cleaning in a cleanroom, the application of coatings for extra protection, and many other techniques.

Hoewel kunststoffen voordelen bieden, is het belangrijk om rekening te houden met de milieu-impact, zoals energieverbruik en afvalbeheer, en te streven naar duurzame productiepraktijken. Binnen BKB Precision zijn we ons hiervan bewust en daar vind je alles over in ons duurzaamheidsrapport.

Early involvement in the design helps to identify manufacturability, optimize material selection, and prevent production problems, leading to higher quality and lower costs.

In addition to PEEK, several high-performance plastics are used in the semiconductor industry because of their specific properties that are essential in demanding environments, such as PEI, PVDF, PTFE, and PI.

Working together on precision

Plastic components for the semiconductor industry require extreme precision, purity, and technical know-how. At BKB Precision, we understand what is at stake in this sector and translate your specifications into manufacturable solutions. With our many years of experience in plastics machining and semiconductor-specific knowledge, we deliver not just parts, but solutions.