Why plastic? The real advantages for medical applications

Medical innovators don’t choose plastic just because. They do so because it offers solutions that are simply not feasible with metal or glass.

- Lightweight and strong

Ideal for portable equipment and ergonomic instruments. - Chemically and thermally resistant

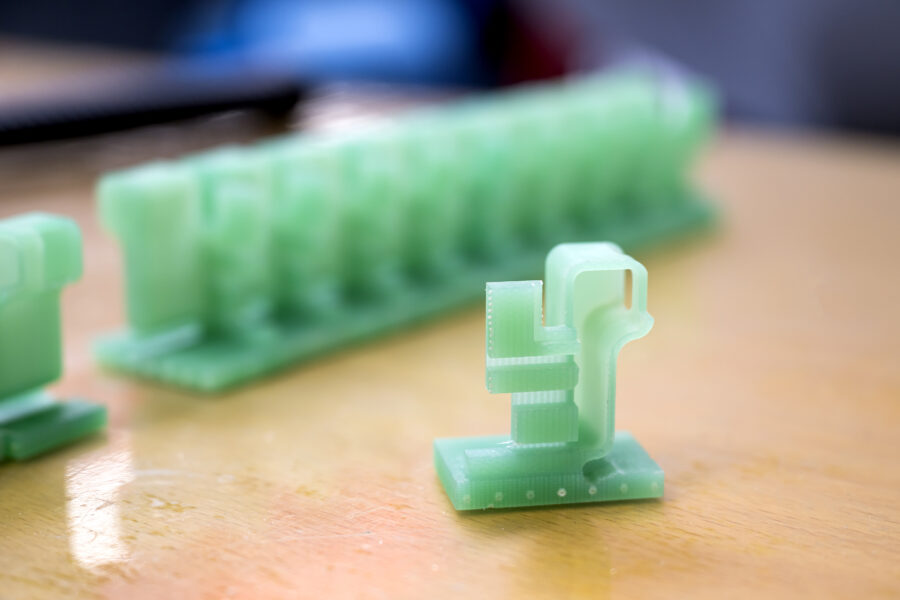

Resistant to intensive cleaning, disinfection, and sterilization. - Design freedom

Complex geometries, microchannels, and optical surfaces are possible—opening the door to new product concepts. - Cost and process advantages

Plastics can be processed extremely quickly, with excellent reproducibility.

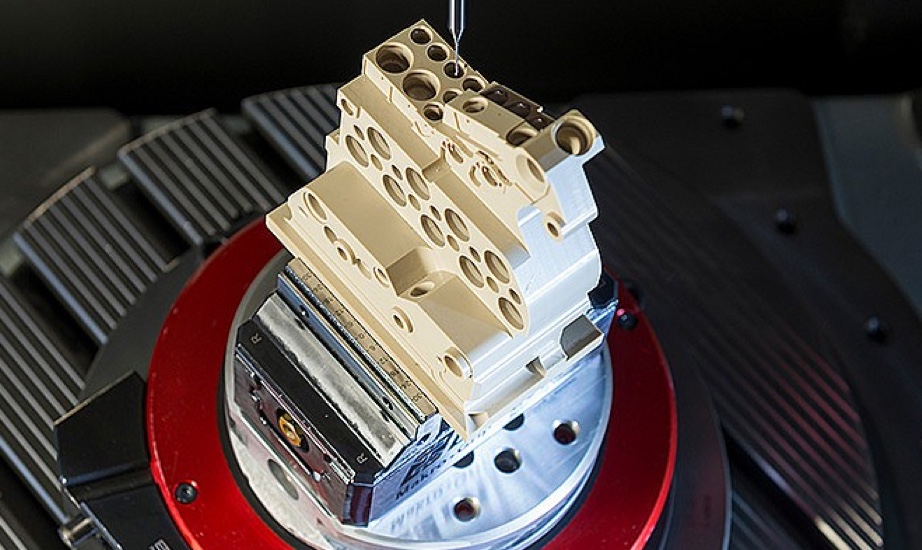

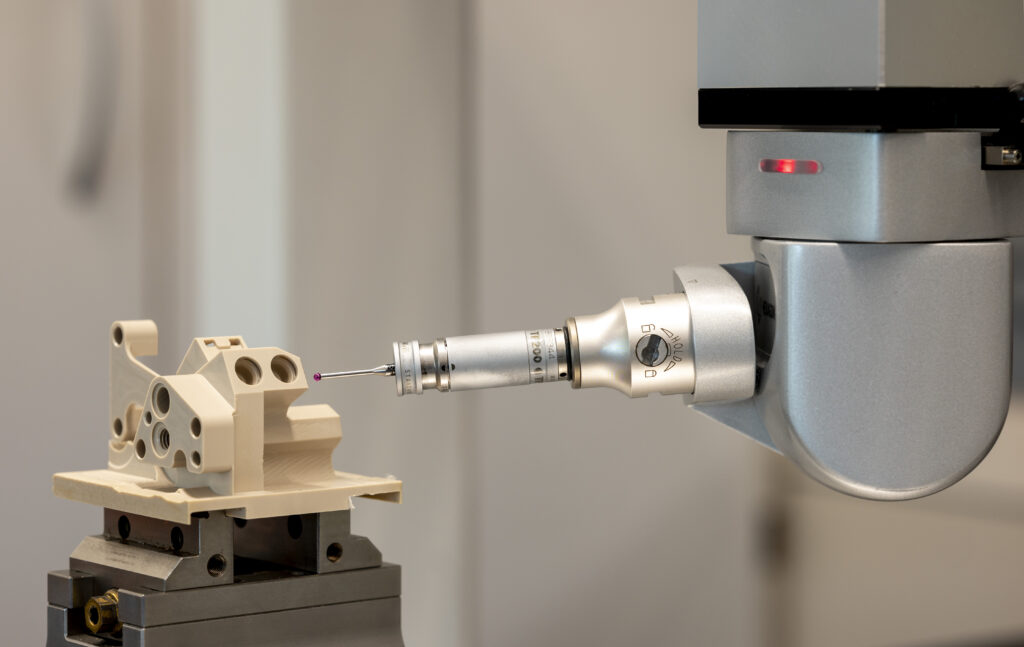

The critical factor: precision

In the medical world, “close enough” is simply not good enough.

A deviation of just a few micrometers can lead to leaks in microfluidics, inaccurate sample analysis, or mechanical failure.

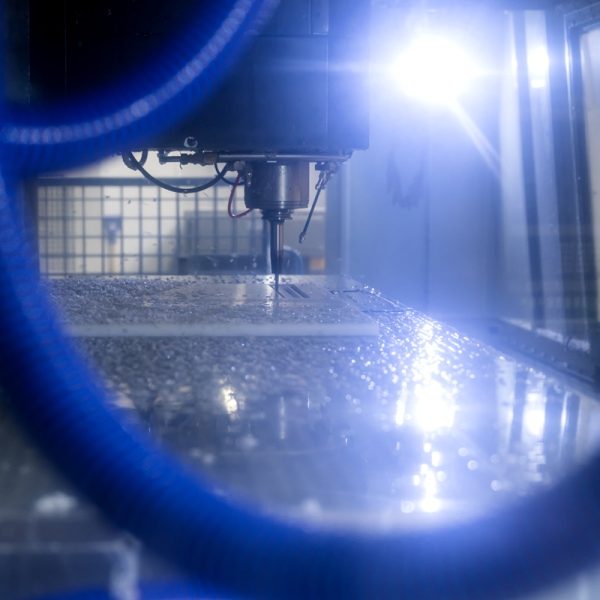

Modern CNC plastic machining makes tolerances achievable that were previously considered impossible. Combined with advanced measurement methods and ISO-compliant production, this creates a manufacturing process that focuses on traceability, stability, and certainty.

Innovation & sustainability: the new standard

The medical sector demands sustainable, traceable production. Recycled and bio-based plastics are becoming increasingly easier to machine and are increasingly being approved for use in medical equipment.

Materials that were considered “too unstable” five years ago are now of sufficient quality for precision machining. This is giving rise to a new generation of components that are both technically and ecologically future-proof. If you would like to know more about the applications and possibilities of plastics, please feel free to contact us.

Material selection and applications: what works where?

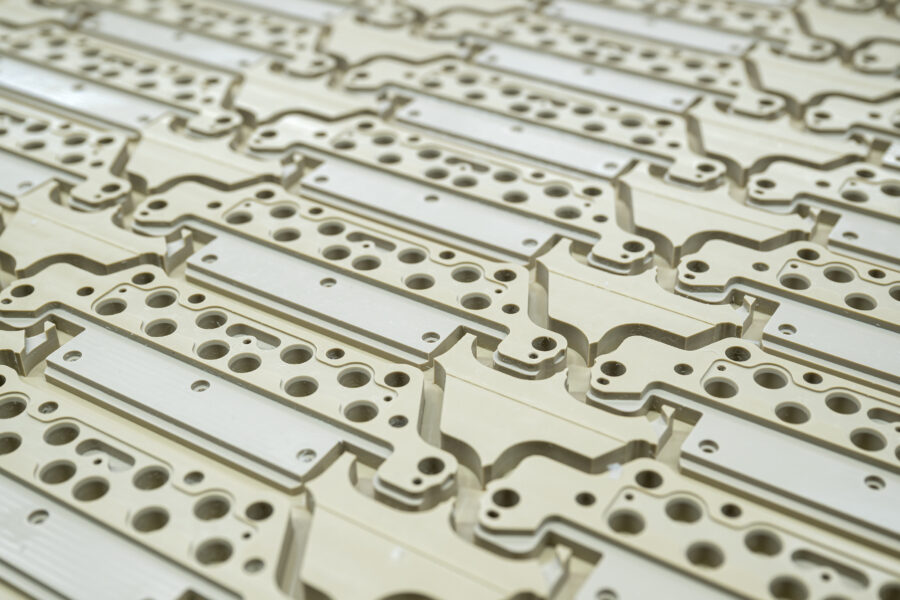

The right plastic directly determines the performance of medical equipment. An overview of the most commonly used materials and their typical applications:

- PEEK

Strong, biocompatible, sterilizable → suitable for surgical components, support structures, and high-end analyzers. - POM

Low friction, highly dimensionally stable → ideal for valves, bearings, gears, and other moving parts. - PET

Extremely dimensionally stable → suitable for flow cells, optical chambers, measuring modules, and precision housings. - HMPE

Wear-resistant and self-lubricating → used for slide guides, guide plates, and moving laboratory parts.

By linking the application to the right material during the design phase, you can prevent problems such as stress cracks, deformation, or inaccurate measurements—and increase the reliability of the entire system.

Plastics machining is more than just a production technique

It is a strategic technology that determines how innovative, precise, and future-proof medical equipment can be. Choosing the right plastics, the right processing technique, and the right partner who understands the market gives you a competitive edge in a rapidly changing market.

Would you like advice on material selection, precision processing, or sustainable alternatives? Feel free to contact us without obligation.