Nikhef

Nikhef is a collaboration between the institute organization NWO (Netherlands Organization for Scientific Research) and six universities in the Netherlands. The company’s goal is to lead Dutch experimental activities in (astro)particle physics, with the mission to study interactions and structure of all elementary particles at the smallest possible length scales and at the highest achievable energy. Mr. Mikkola adds that what’s admirable about Nikhef is that they not only have researchers but also technicians and engineers building the experiments.

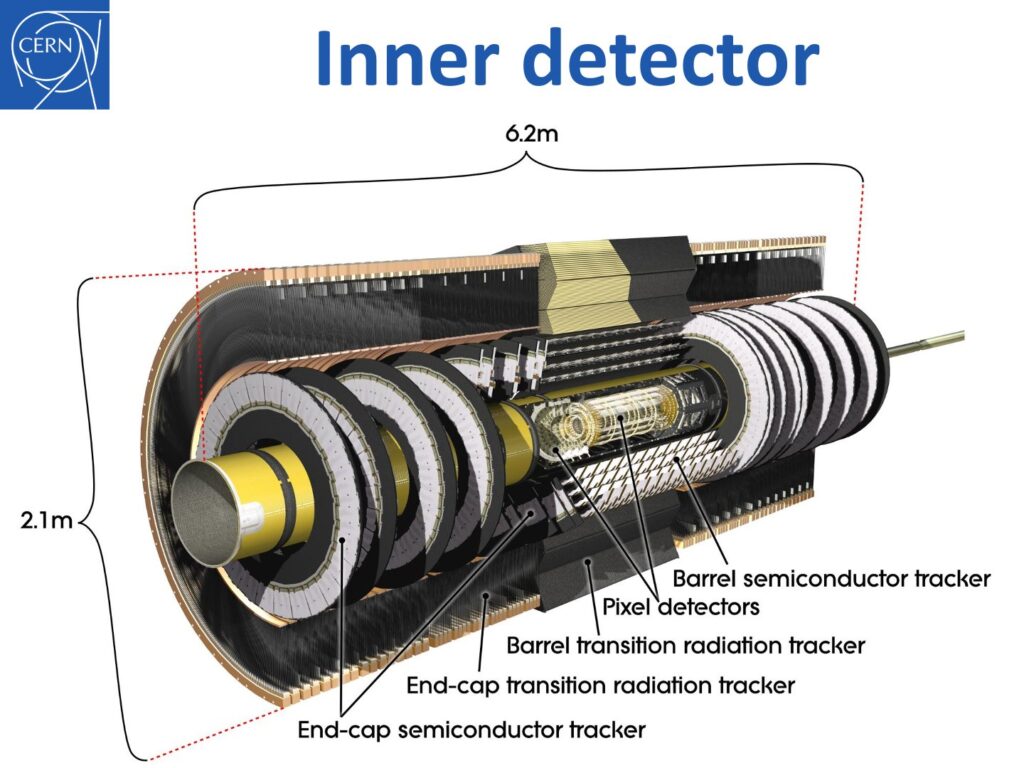

ITK detector Atlas

Since the 20th century, Nikhef has contributed to various experiments at CERN, including Alice, LHCB, and ATLAS. The ‘ATLAS’ experiment stands as one of the most complex and precise experiments to date. The ATLAS machine measures 44 meters in length and 25 meters in width, with Nikhef responsible for the operation of the ‘Inner Tracking Detector,’ measuring only 6.2 meters in length and 2.1 meters in width. Mr. Pool adds that the inner tracker constitutes an important piece of the puzzle, as their detector measures the direction, momentum, and charge of particles produced in the collisions. This crucial role is further illustrated in the drawings below of the ATLAS and the Inner Detector.

BKB Precision

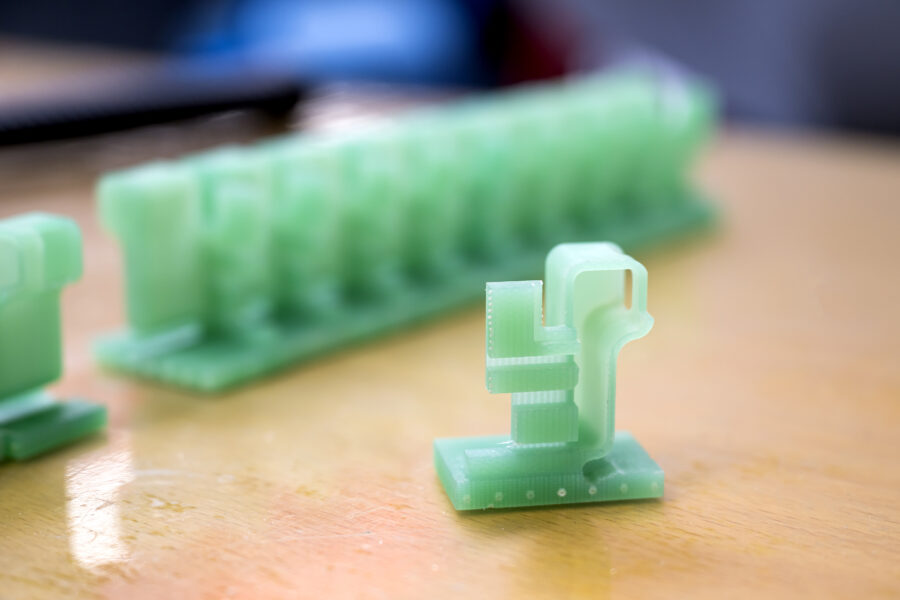

Mr. Mikkola mentioned several reasons why BKB Precision was chosen to manufacture products for the ITK. “Expertise in high-performance plastics, effective communication, our visit to BKB Precision, and having our own cleanroom are some factors that convinced us to choose BKB Precision. The product produced by BKB Precision requires utmost precision and must meet strict specifications; otherwise, the functionality within the entire tracking process is at risk. BKB Precision embraced this challenge and demonstrated a prompt response to improvements, actively seeking suitable solutions.” As is often the case at BKB Precision, we initially manufactured the product from PMMA to ensure proper flow and alignment of the holes.

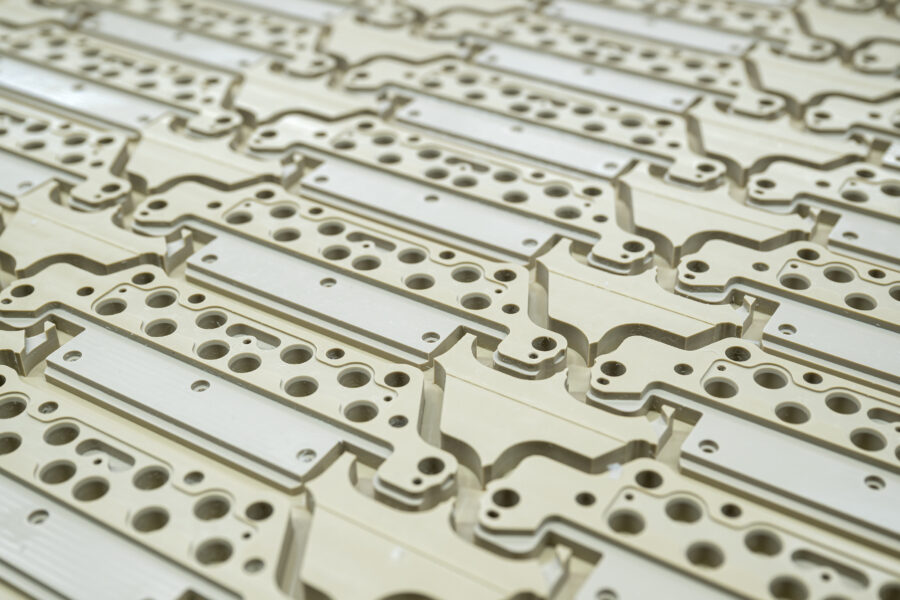

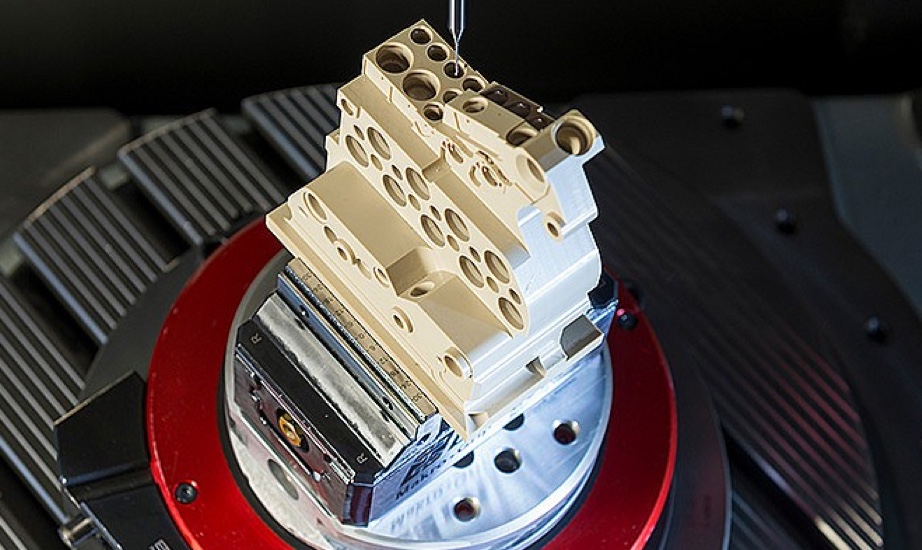

The products we manufacture at BKB Precision for Nikhef are part of a composition for facilitating the passage of a multitude of cables for the Inner Tracker Strip End Cap. The greatest challenge lies in the precise finishing of various components, where we must strive for perfection in flatness, roughness, tolerance, and dimensions. All products are machined using 5-axis technology and vary in size from 40mm to approximately 560mm.

The production of the ITK Strip end cap for Cern

Delivering a product like the ITK Strip end cap to CERN is definitely no easy task. Various factors must be taken into account, including radiation levels, magnetic fields, and the limited underground space. Additionally, there is the challenge that the product must function correctly from the outset, and final testing can only occur after installation. Quality and precision thus play a crucial role, as errors are not tolerated. Nikhef strives to ensure this by collaborating with partners who communicate clearly, can guarantee quality, and conduct thorough checks. In short, a partnership with a collaborator like BKB Precision is essential.