Upgrading Our Machinery

At BKB Precision, we recently took a significant step towards modernisation: two outdated Hermle C22 milling machines were removed and replaced by two state-of-the-art Hermle C32 machines. During this upgrade, we also treated the production floor in that area with a new coating to protect it against wear and chemicals. This makes the workspace safer, more durable, and easier to maintain.

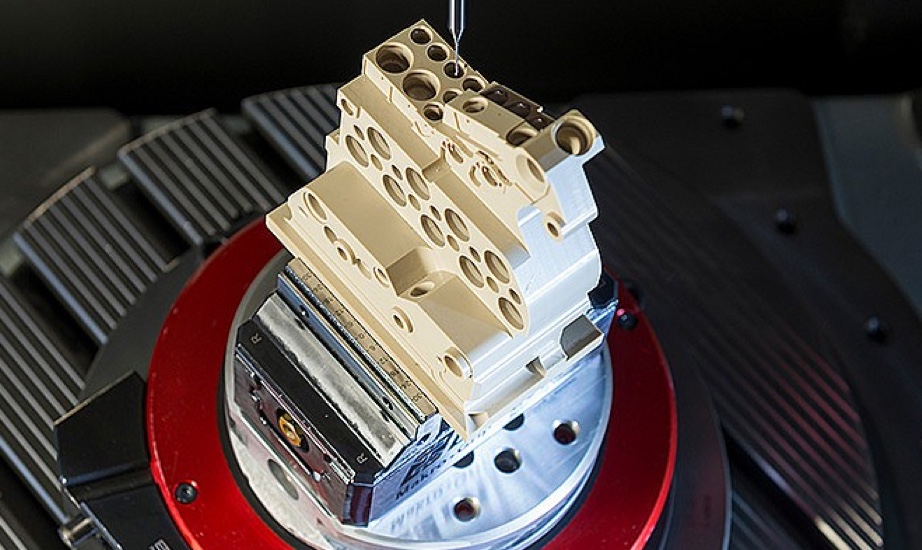

The entire process—from dismantling and floor treatment to installation—was completed smoothly within just four weeks. The new 5-axis milling machines have been successfully tested and are currently going through a precise release process before being fully integrated into our regular production.

From Pallet Changer to Robotic Arm

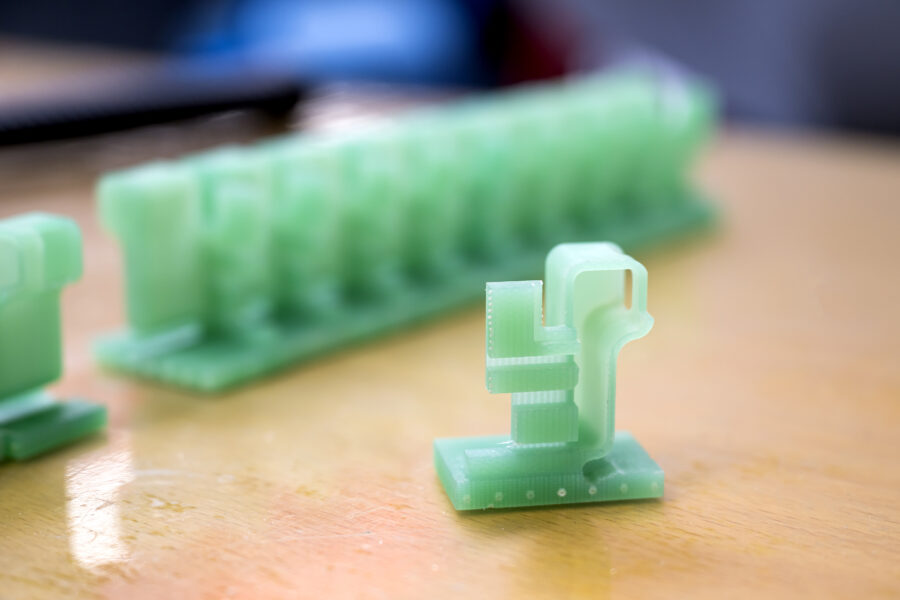

The new 5-axis C32 milling machines are equipped with an RS1 robot for automated product changes, enabling 24/7 unmanned production. This offers far more possibilities than the older C22 machines, which still relied on a pallet-changing system.

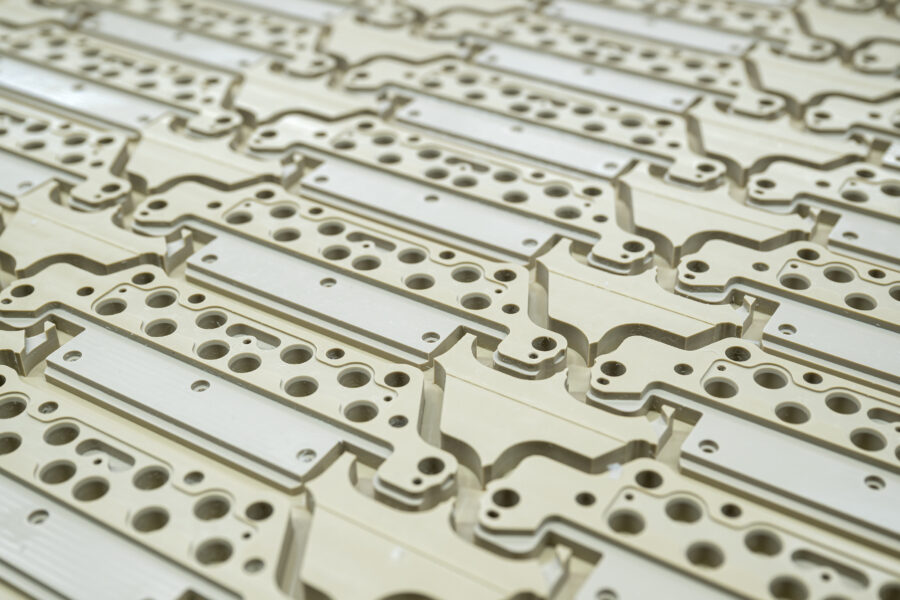

“Thanks to the new C32s, we’re using our space much more efficiently. Although we replaced two machines with two new ones, we’ve created room and standardisation that will allow us to scale up more easily in the future. And all that with higher speed, better precision, and greater versatility,” says Sales Director Van de Burgt.

By choosing Hermle’s C32 machines, we maintain uniformity in our machinery. This ensures that our team’s expertise seamlessly transfers, allowing for a smooth transition in daily operations.

Looking Ahead

“Even in challenging market conditions, BKB Precision continues to invest in the latest technologies,” says Van de Burgt. “Because standing still means falling behind. We are committed to building a future-proof machine park so we can continue to guarantee the highest quality and delivery reliability to our clients.”

And the investments don’t stop with the replacement of the C22 machines. Additional new machines are on the way and will be installed later this year. Stay updated via our news page or social media channels.

Curious what these developments mean for your project? Feel free to contact us, we’re happy to think along with you.