Trend 1: CNC milling

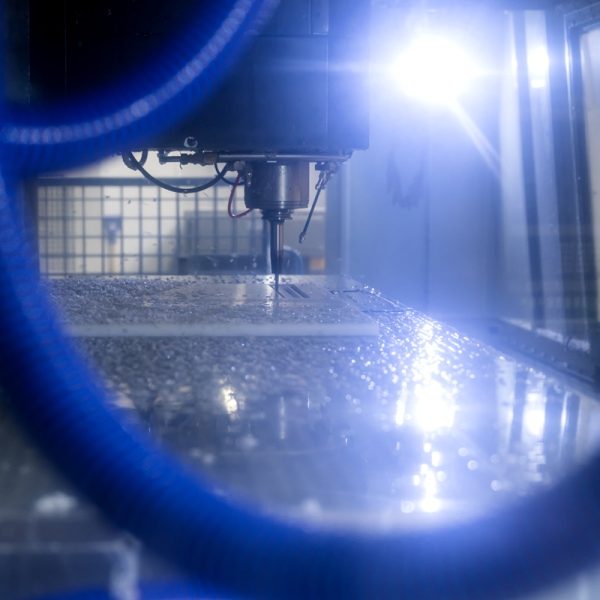

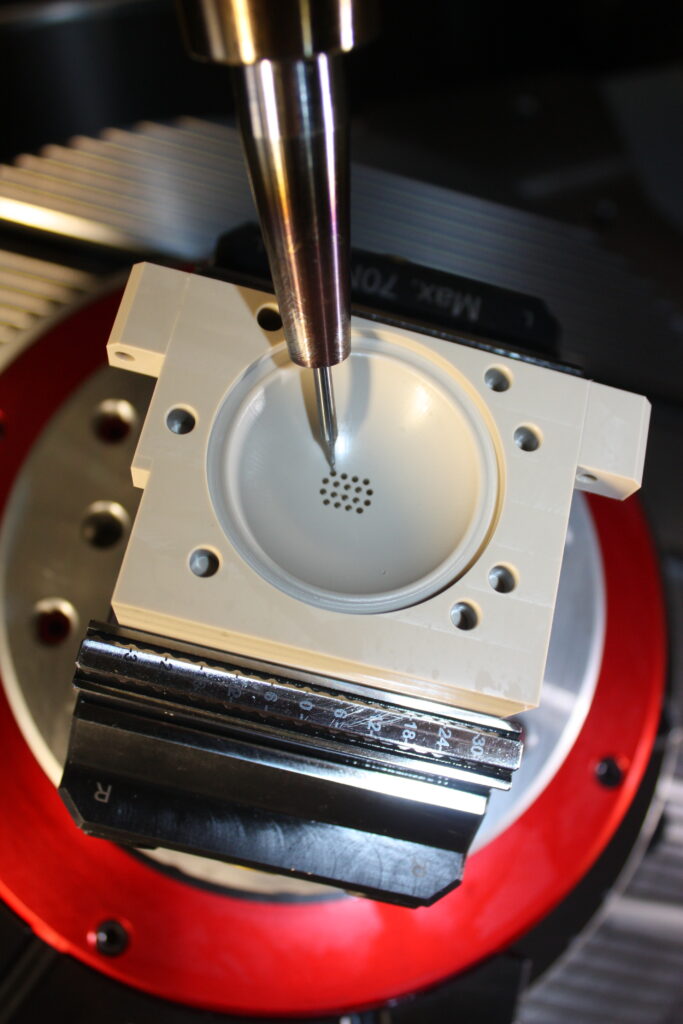

The way we mill plastics is rapidly changing thanks to technological developments. Where not so long ago it was skilled handwork, nowadays it is computer controlled. We call this CNC milling, where CNC stands for Computer Numerical Control. This means you can work faster and more accurately. For example, our advanced turning-milling machines can accurately process plastics of up to 3μm.

Moreover, computer-controlled milling makes it possible to carry out more complex procedures. This trend seamlessly meets the market’s need for innovative high-tech plastic products made to the highest possible quality requirements, and which are also manufactured with the greatest possible precision. In addition, CNC milling also means one can get a clear picture of complex designs at an early stage so that engineers still have the freedom to develop them further.

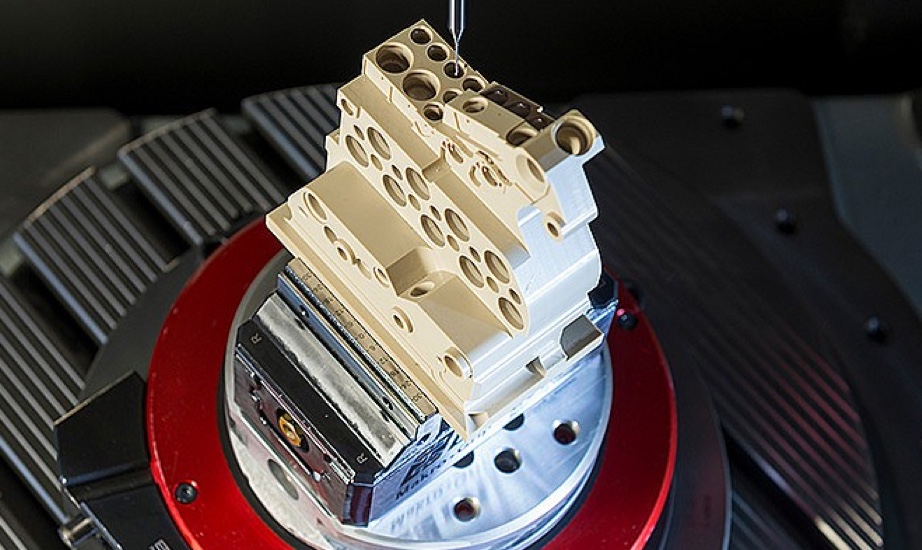

Trend 2: 5-axis simultaneous milling

Another technological feat we know everything about at BKB Precision is 5-axis simultaneous milling. This is the most advanced method of machining, in which all machining axes can be controlled simultaneously. It’s not for nothing that this technique is often used in the manufacture of highly complex products.

We have six such machines in our air-conditioned production hall, which includes robots. Thanks to robot loading, we can work even more efficiently and accurately. Trends and developments in this field are also advancing rapidly. The first robots to use self-learning algorithms are already on show at trade fairs. Of course, we keep close track of these developments.

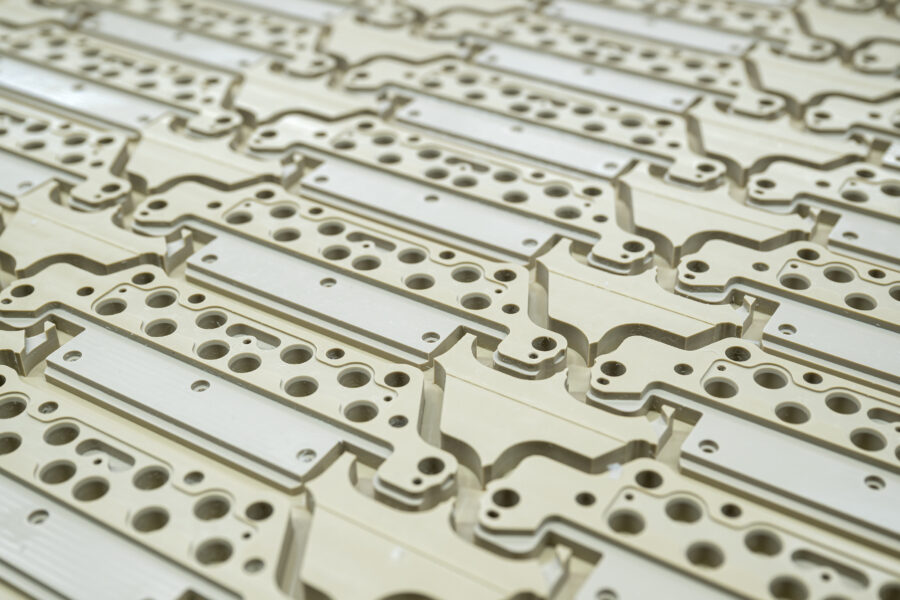

Trend 3: Manufacturing plastic manifolds from high quality plastic

A plastic manifold has several branches or pipes. An important trend within the professional market is to have such a product manufactured from high-quality plastic. This is a highly future-proof solution at a relatively low cost.

In addition, plastic offers more design freedom and very high chemical resistance. High performance plastics such as PEEK or PEI in particular are excellent alternatives to metal components. Their low weight also means that highly dynamic systems perform even better.

Trend 4: High performance plastics milling

Another trend we cannot ignore is the growing demand for high performance plastics. These are plastics which perform well under extreme conditions, with qualities such as a high degree of temperature and chemical resistance. This makes such plastics ideal for the high-tech industry.

Consider applications in the aerospace industry, medical industry and semicon industry. Some high performance plastics can even be used as an alternative to steel. Thanks to our many years of experience in milling high performance plastics, we know all about its possibilities and can offer our customers the best advice in the field. You can also have your prototypes developed with us.