High-quality plastic components for the defense sector

Precision machining of high-performance and technical plastics for defense applications that meet the requirements and standards as known in the defense sector.

In the defense sector, reliability is not a choice but an absolute requirement. Behind the scenes, specialized suppliers work on components that must perform under extreme conditions. One of those crucial links? High-quality plastic machining. Precision, material selection and discretion come together in a discipline where nothing is left to chance.

What makes plastic machining in defense so demanding?

Plastic machining in the defense sector is demanding due to the exceptional conditions in which components must perform and the strict requirements they must meet. Plastic parts must, often for years, function perfectly without any margin for deviation. From material selection and dimensional stability to resistance against impact and chemicals: every detail matters. The margin for error? Simply does not exist.

At BKB Precision we have experience in producing plastic components for defense and we know better than anyone that this industry demands absolute precision, in-depth material knowledge and a fully reliable production process within a well-secured working environment. We not only supply separate components but also complete products, applying techniques such as inserting inserts, gluing, laser marking and welding. This way we ensure a complete end result that is immediately deployable.

The role of plastic in defense applications

Plastics play an increasingly important role in various defense applications. Think of precision parts for communication systems, housings for electronic equipment, wear-resistant components in vehicles or lightweight structures for portable equipment. Due to their versatility, high-performance plastics can be machined into complex shapes with minimal tolerances, maximum reliability and a reduction in weight.

This is why defense increasingly chooses plastic strategically

Plastics repeatedly prove their value in the defense industry. Thanks to their low weight, high strength and excellent resistance to extreme environmental influences they increasingly prove their added value over metal components. Even a small weight reduction in equipment or material can make a significant difference in the mobility of military personnel without compromising reliability or durability.

At BKB Precision we see that more and more parties in the defense sector are consciously choosing plastic as a strategic material and BKB Precision as a reliable partner. Curious how we can support your organization with high-quality plastic solutions?

Defense demands high standards and so do we

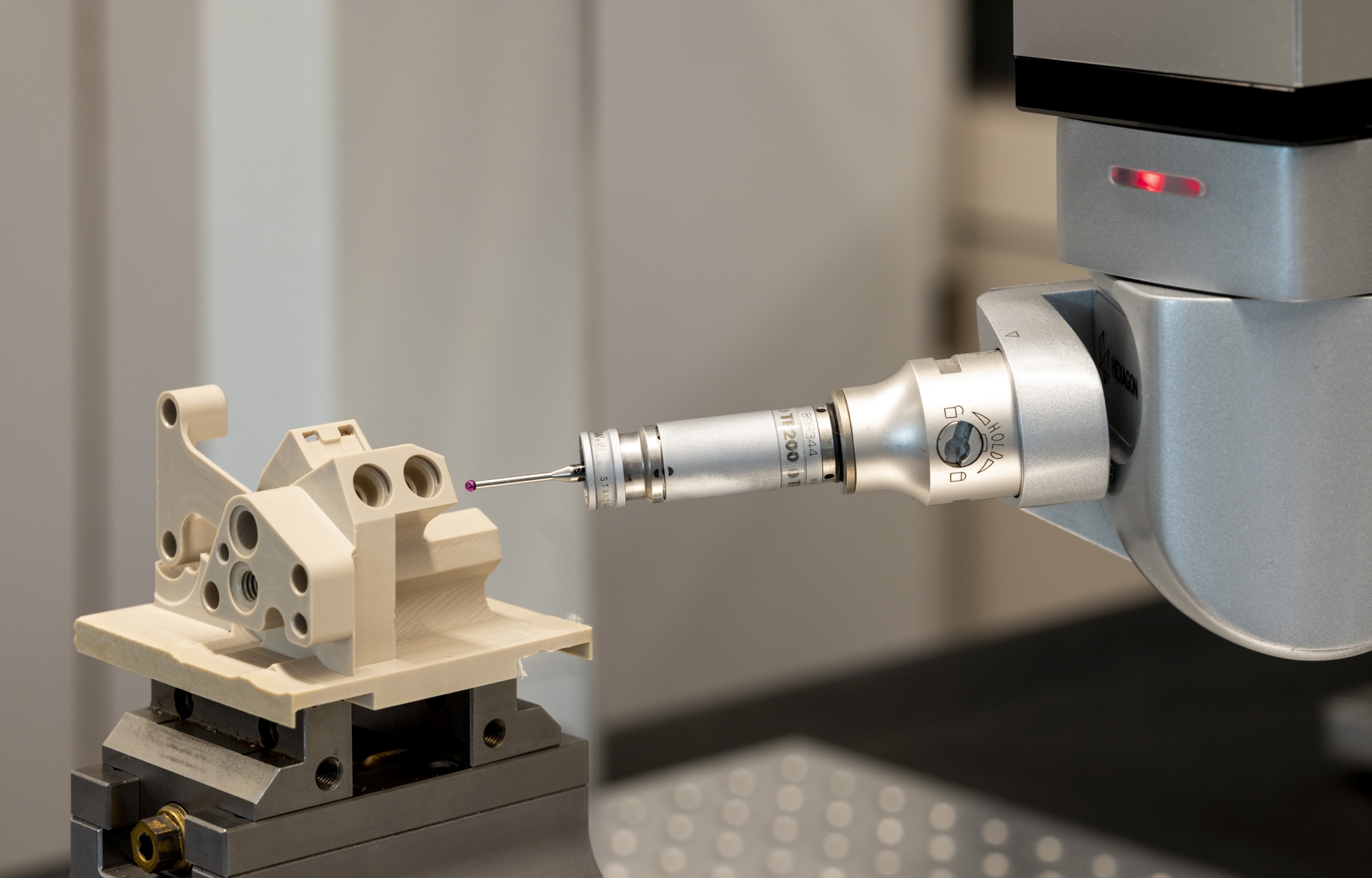

In the defense sector quality is not an option but an absolute requirement. Components must function flawlessly under the most extreme conditions and that starts with a meticulous production process with strict quality control. At BKB Precision quality is central to everything we do, from material selection and machining accuracy to cleaning, packaging and documentation. Our processes are set up to meet the strict requirements of defense customers who leave nothing to chance.

Want to know more about our quality assurance?

Customer case from the defense sector: precision work under high expectations

For various international defense companies we supply complex plastic components within extremely tight tolerances. As a supplier for Airbus and Thales we know what is required in this demanding sector: speed, creativity and absolute precision.

"Their credo ‘making the almost impossible possible with plastic’ has in my opinion been realized. You do not call on their creativity in vain when you search for solutions with them. They know a lot about and can do a lot with plastic." according to Geert van de Merwe, Purchasing Manager at Thales Netherlands. Thanks to our climate-controlled production environment and specialist knowledge we remain a reliable partner for innovative applications within defense.

Most frequently asked questions in the industry

Which plastics are suitable for defense applications?

Think of high-performance plastics such as PEEK, PPSU, PTFE, POM, PEI (Ultem) and glass or carbon fiber reinforced materials but also foam materials such as Airex or Rohacel. These offer strength, chemical resistance, dimensional stability and temperature resistance.

Does BKB Precision comply with military standards and specifications?

Our processes are designed for stability, precision and reliability. Because all our products are custom made and we handle customer information and designs discreetly our working method and quality standards seamlessly match the expectations within the defense sector. Customers in this field can count on a safe professional and committed cooperation.

How does BKB Precision guarantee confidentiality in defense projects?

Through NDAs, closed production environments, controlled access procedures and secure data processing. Discretion is an integral part of our working method. In addition all employees sign a code of conduct.

Can BKB Precision also contribute in the engineering phase?

Absolutely. We are happy to collaborate with engineers to optimize material selection, manufacturability and tolerances at an early stage of the design. As an early supplier involvement partner, we actively think along from the first design phase so that the final product is technically feasible, efficiently manufacturable and of consistent quality.

What tolerances can you achieve in plastic machining?

Depending on the material and machining method, we can achieve tolerances of up to ±0.001 mm, which meets the requirements in many defense applications.

Do you have any other questions?

Do you have any other questions or would you like to speak with one of our specialists regarding the possibilities of plastic machining within the defense sector? Then feel free to contact us using one of the options below.