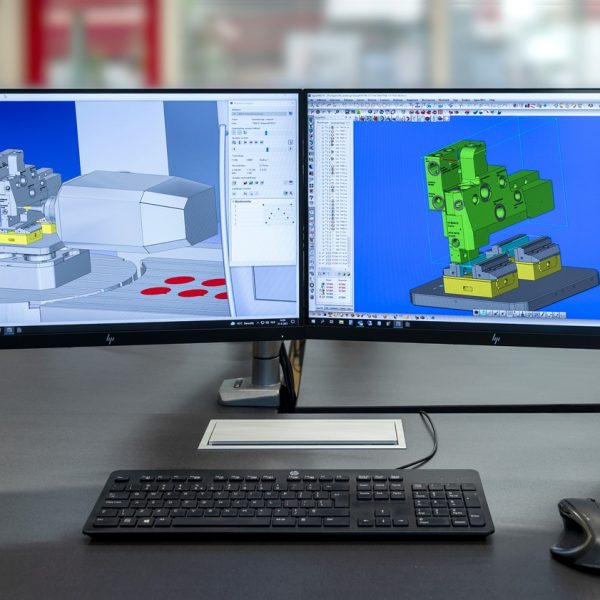

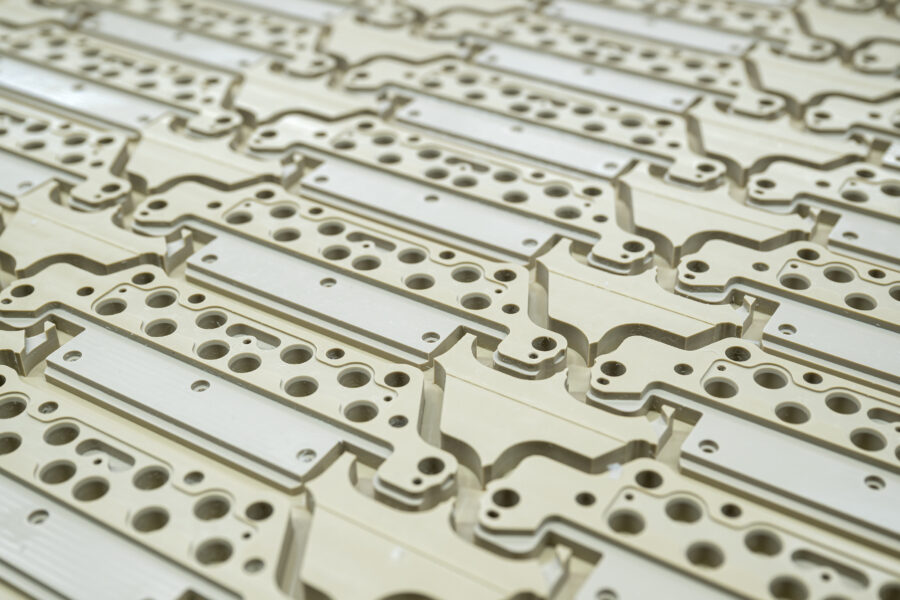

Knowledge and a hightech machinepark

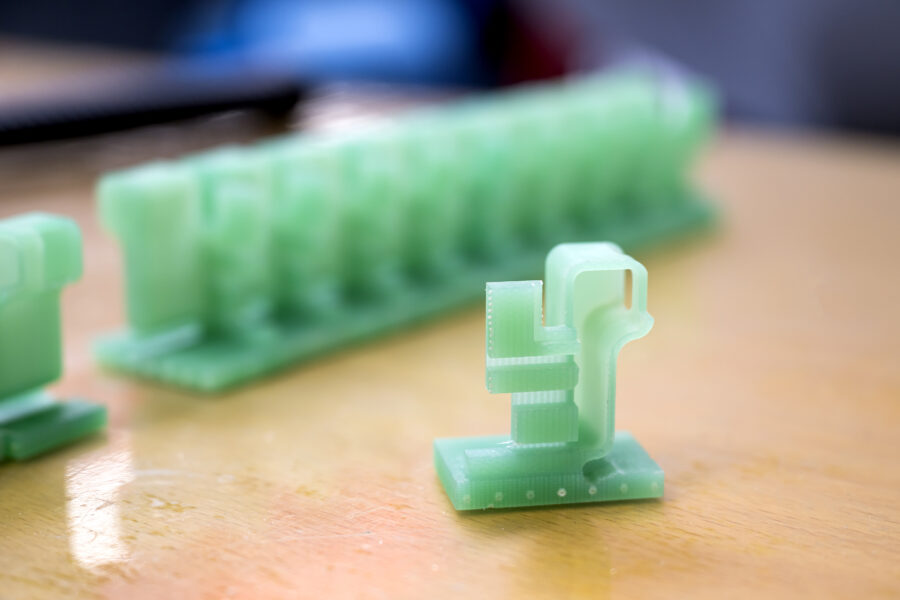

We share our knowledge with engineers by developing and designing narrow specified plastic parts. From prototyping and individual pieces to production of smaller series as well. We produce on the latest CNC controlled machining centres, up to 7 axes. We clean (class 7) and assembly, if needed under cleanroom conditions.

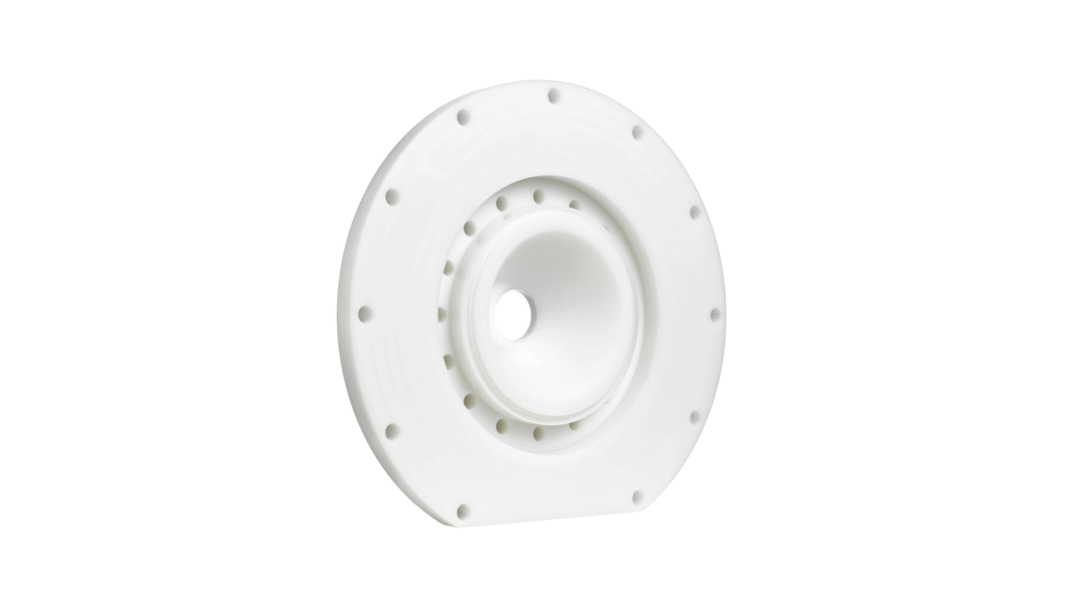

Various plastics

BKB Precision works with plastics that demonstrates the utmost precision and maximum reliability throughout every stage involved in the complex and accurate machining of the parts. We only machine (milling and turning) plastics and no metals. Because of the danger of metal ion contamination, we exclude any contact with metal materials during production.

Stringent requirements

BKB Precision works with High Performance Plastics that comply with stringent requirements, like:

- High thermo-mechanical strength

- Minimal thermal expansion

- Low particle generation in bearing and wear applications

- Good chemical resistance to acids, alkalis, greases and solvents, hydrogen peroxide, demineralised water, hot steam

- Good plasma resistance

- Minimal outgassing under vacuum

- Minimal extraneous ion content

- Good electrical insulating properties and defined static conductivity

- And last but not least: the plastics should comply with strict cleanroom production standards

Diverse applications

BKB Precision is experienced in machining parts for Semicon products/applications like:

- Wafer cleaning equipment

- Wafer etching equipment

- Wafer carriers

- Chemical tanks

- Turntables

- High Purity Piping systems

- Microelectronics

- Vacuum chucks

- Tubes and fittings

- Lined tanks

- Circuit boards

- Filtration and diffusion equipment

- Static control applications