High pressure cooling and multi-tool

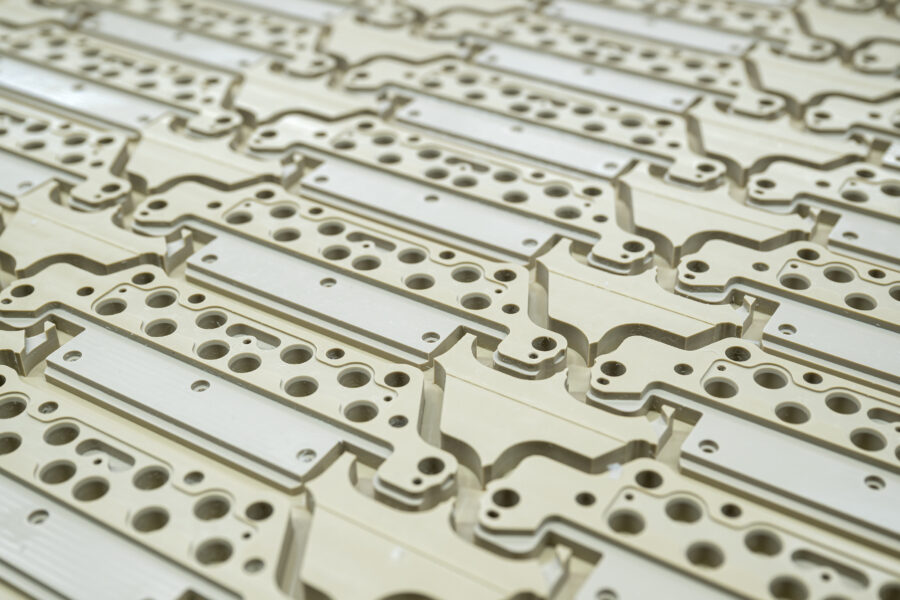

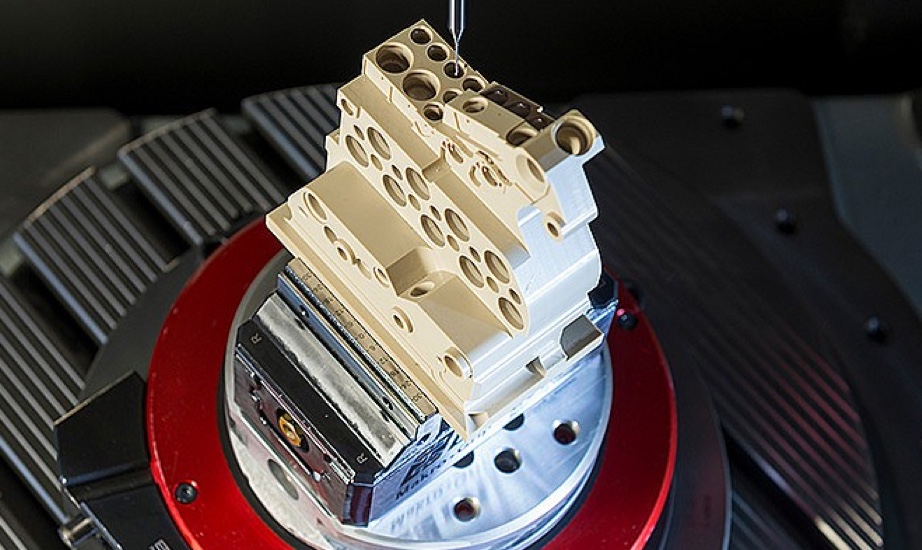

The stable construction ensures high accuracy with the most complex applications and at different temperatures. The construction of the machine prevents vibrations while being in operation. The machine also has high pressure cooling that allows deep hole drilling; drill holes that are 10 times deeper than the original diameter. With the multi-tool up to 4 tools automatically can loaded and used.

The extensive editing capabilities ensure that a more effective production of parts can take place which is beneficial to the quality of the product. The Okuma Multus B200II is equipped with six programmable axes that ensure 5-axis modification simultaneously.

“Due to the growth of the company, the capacity of the current machines was no longer sufficient. An additional advantage is that we can continue to produce at a high level and guarantee quality, “says Mannes Westhuis, Managing Director.