We work for, among others

Plastic CNC Milling

What exactly is plastic milling? In short, it’s the process of using hand or machine tools to shape and change the form of the material. By removing parts of the material, often in the form of curls. The original form of the product changes, and in this way, the desired shape is achieved.

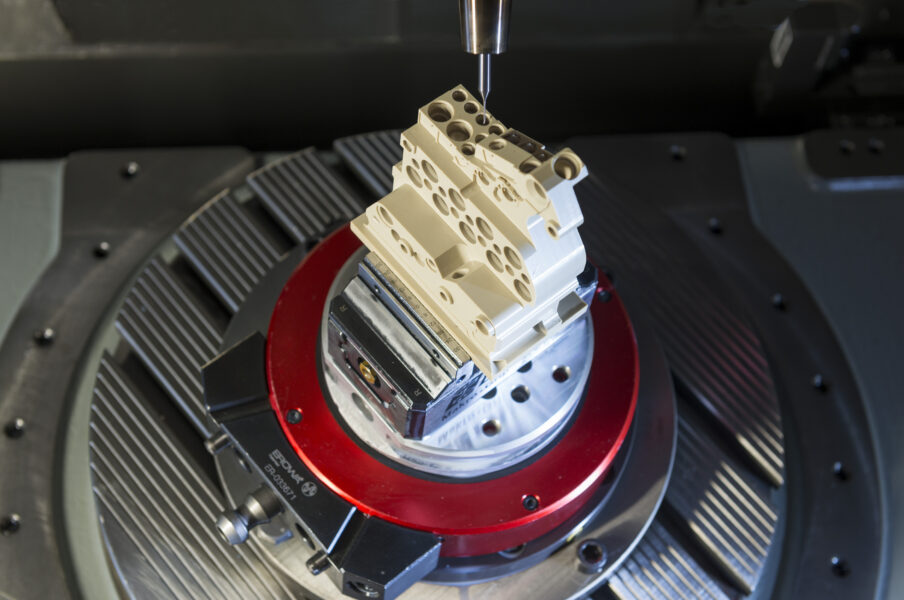

Plastic milling at BKB Precision is done in a fully computer-controlled manner. That’s why it’s also called CNC milling. The collaboration between programmers and millers ensures that we always deliver the highest quality. Our high-quality clients continually challenge the team with requests for new precise products, constantly elevating our milling capabilities. Curious about what we can do for you? Then get in touch with our dedicated team.

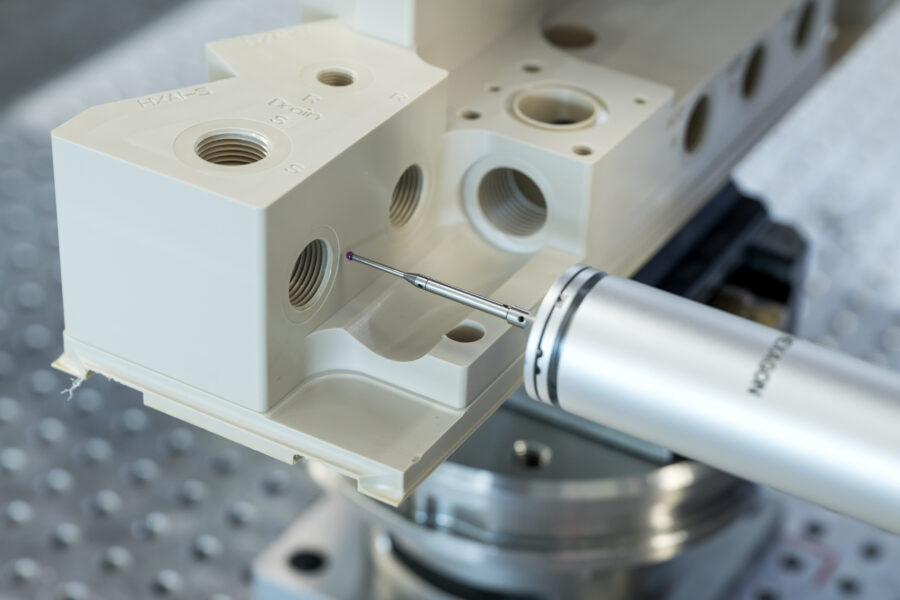

Precision and accuracy

CNC milling of plastic requires specialized knowledge and craftsmanship. Each type has its own unique characteristics and machining possibilities. The specialists at BKB Precision are familiar with the specific properties of all kind of differtent types and work according to strict quality policies to guarantee the best quality to our customers.

Various Types of Plastics

Processing PMMA, POM, PETG, PEEK, PTFE, or perhaps polycarbonate? Within machining with CNC milling, almost anything is possible. We process virtually all imaginable plastics, taking into account their unique properties, as a matter of course. Explore all the properties of the all the different types via the button below.

Sustainability as a Top Priority

At BKB Precision, we place a high priority on sustainability. Through innovative techniques, conscious material choices, and many other initiatives, we strive to contribute to a greener future. Learn more about our sustainable initiatives in our sustainability report.

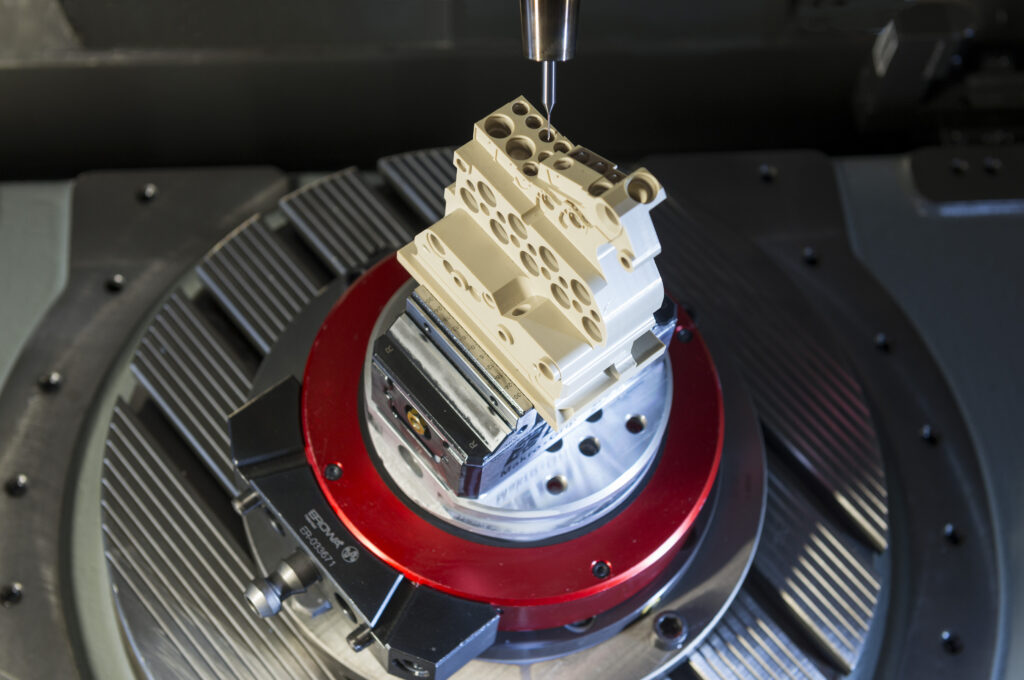

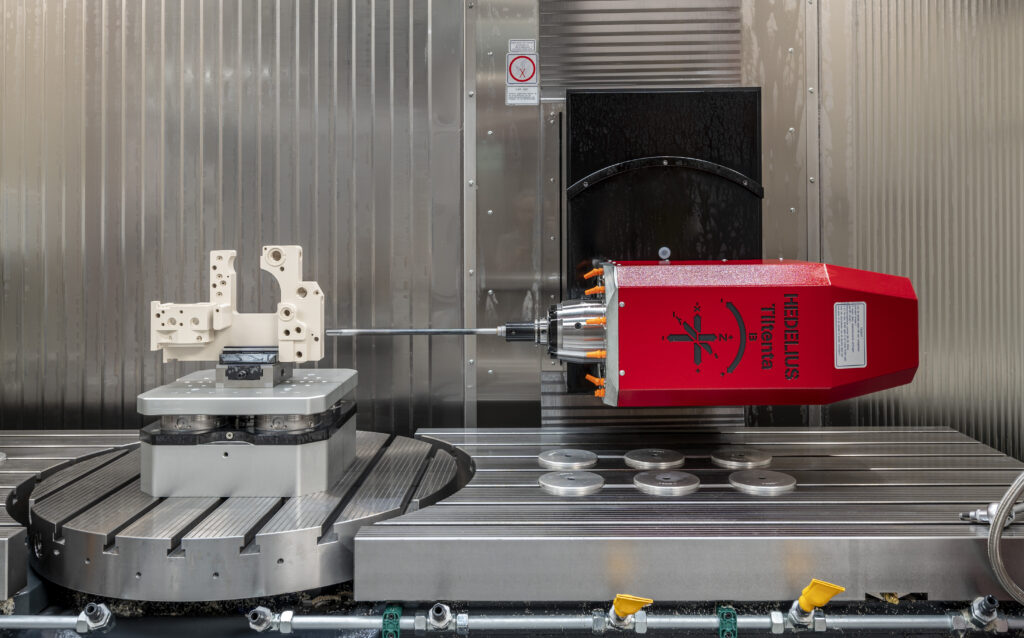

Innovative CNC Milling Technologies

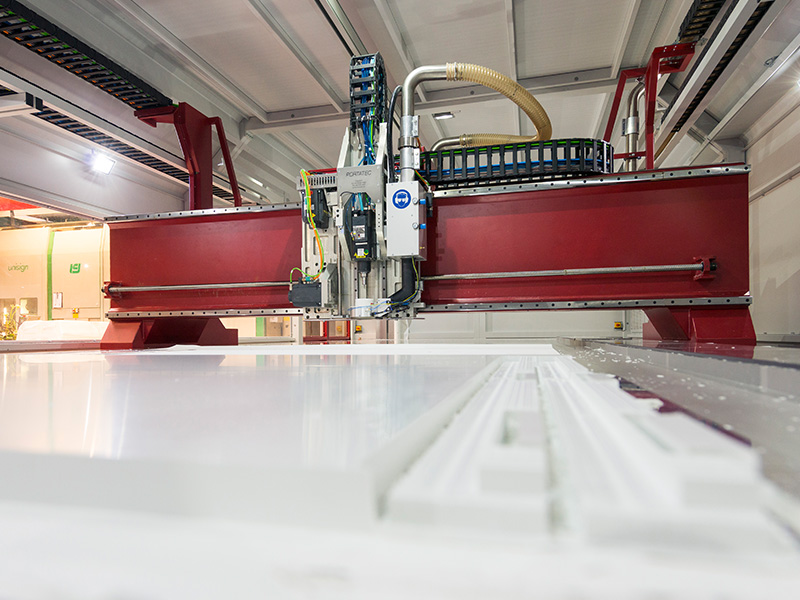

Plastic milling at BKB Precision takes place in a conditioned production hall with advanced machines. These machines are used for 3- and 4-axis CNC milling, up to complex 5-axis simultaneous CNC milling. Additionally, we have portal milling machines at BKB Precision. These milling machines can accurately and precisely mill large sheets.

Plastic Milling and Turning Works

Plastic milling is not the only way we machine at BKB Precision. We also employ CNC turning in combination with our state-of-the-art machine park to produce the most advanced plastic milling and turning works. With our expertise in plastic milling, we offer tailor-made solutions for various industries where precision and quality are of paramount importance. Read more about machining and turning through the links below!

Frequently asked questions about CNC milling

CNC milling involves the high-precision machining of plastic blocks or sheets. Simultaneous axis movements create precisely fitting geometries. At BKB, we also mill transparent, chemical-resistant, or heat-resistant high-quality plastics.

Production is ISO 9001 certified with documentation and traceability. Cleanroom processes are in place for sensitive sectors (e.g., medical technology). Find out everything about the standards we meet and how we guarantee quality on our quality page.

At BKB, we process standard plastics such as PMMA and PP, engineering plastics such as PETP and POM, and high-performance plastics such as PEI, PEEK, or PTFE and foam materials. Since the materials differ greatly from one another, for example in terms of their temperature resistance, stability, and hydrolysis resistance, the choice is tailored to your individual requirements.

We work with production tolerances of up to ±3 µm. This is possible thanks to our climate-controlled production environment, high-precision 5-axis machining centers, automated production processes, and the use of state-of-the-art measurement technology—all geared toward consistent precision, even in series production.

Additional machining steps include the assembly of (sub)assemblies, adhesive bonding with tailored adhesives (including UV) and welding processes such as infrared and hot gas welding. Individual adhesive bonding techniques are also possible. Cleaning in accordance with phase 4 and processing under ISO class 7 conditions complete our range of services. We would be happy to advise you on the right processing steps.

Yes, medical and cleanroom requirements according to ISO Class 7 and ISO 13485, including packaging, are possible.