We work for, among others

5-Axis (Simultaneous) Plastic Milling: An Explanation

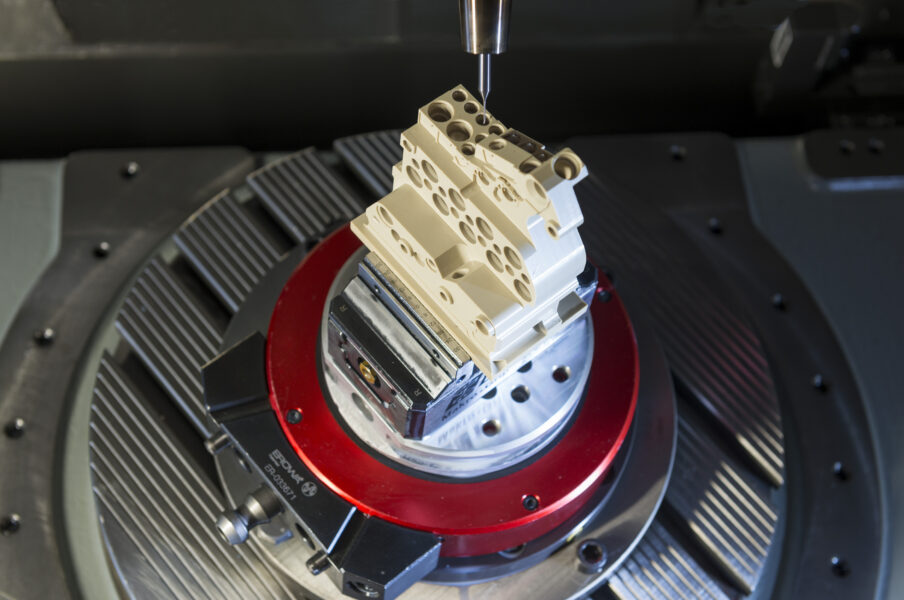

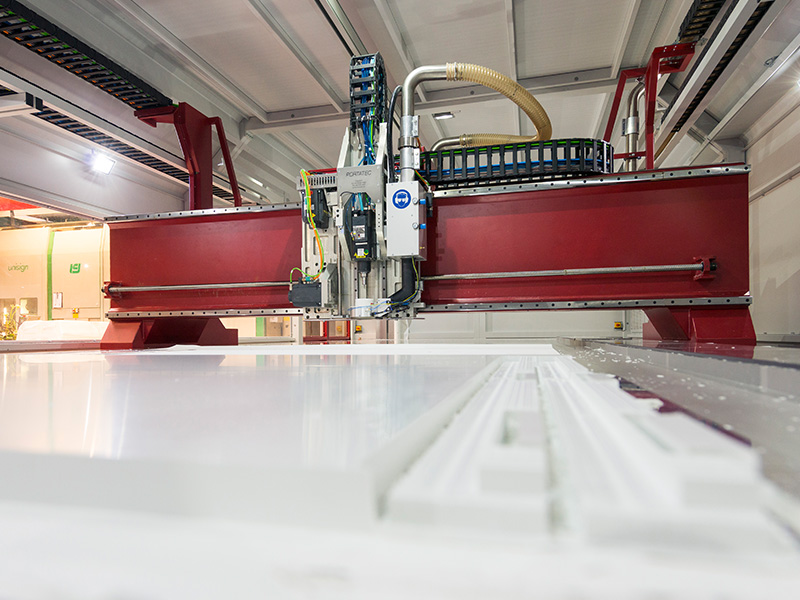

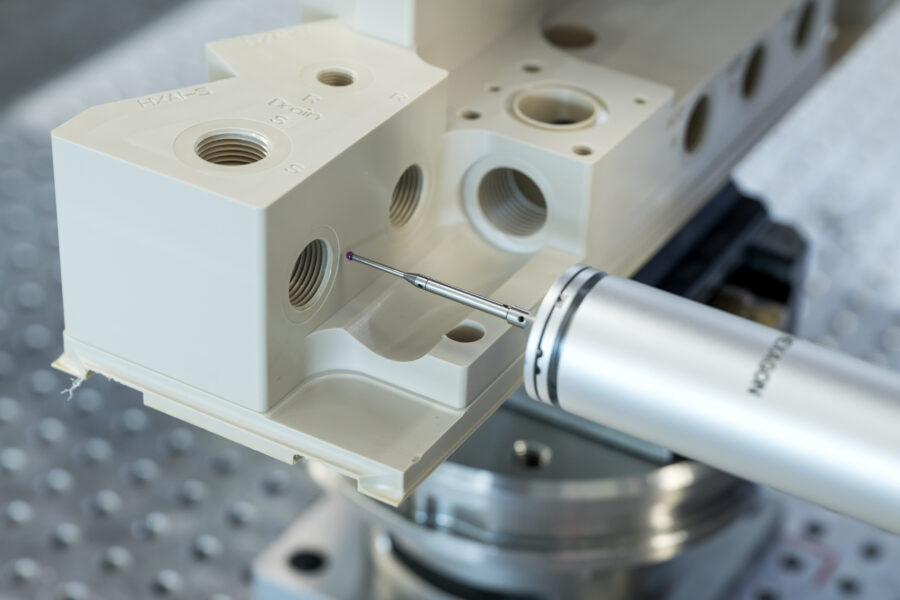

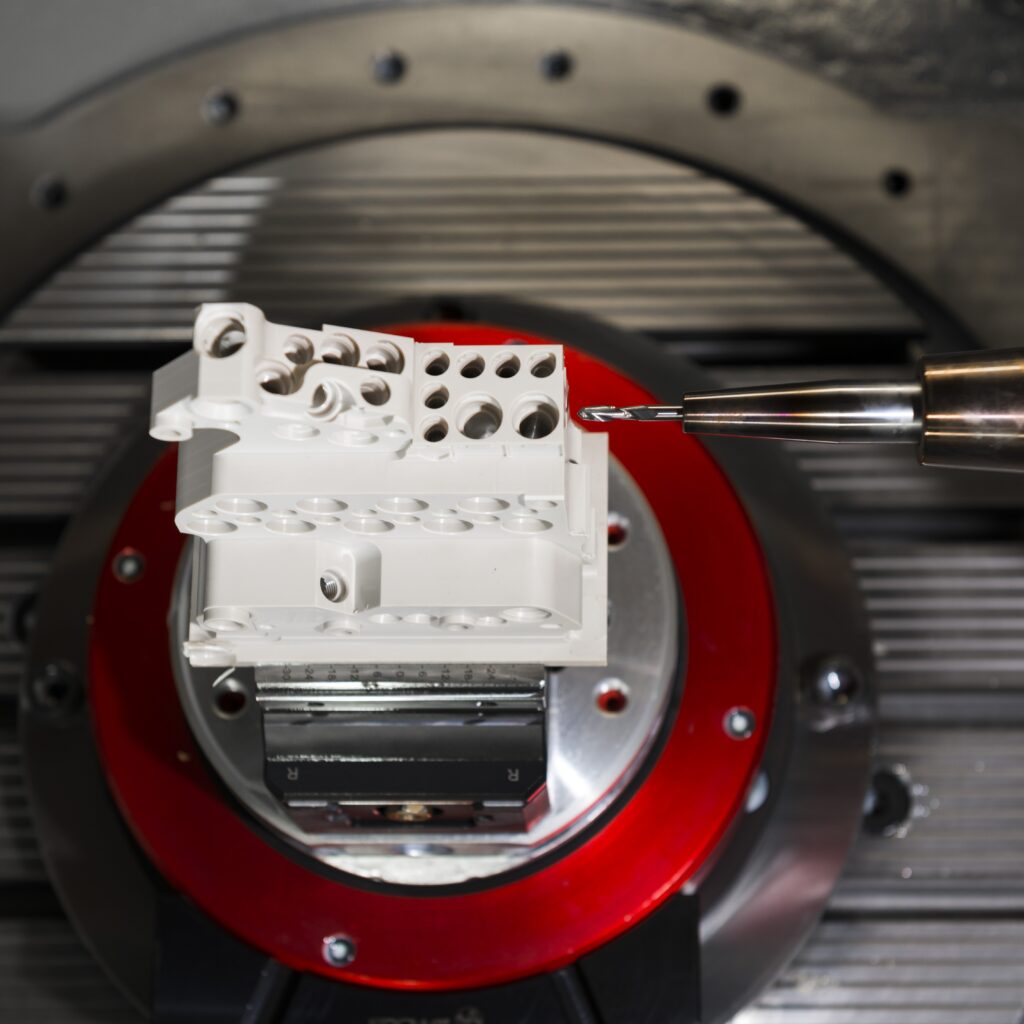

Unlike 3-axis milling, 5-axis milling enables machining at different angles. The cutter moves along the X, Y, and Z axes while the head can be tilted. This method allows the product to be machined not only from the top but also from the left and right sides.

This method offers significant benefits. The product can be milled faster while maintaining the same precision. Higher tolerances can be achieved during plastic machining. Additionally, more complex operations can be performed with this method.

At BKB Precision, we also offer 5-axis simultaneous milling, the most advanced method of CNC machining where all machining axes are controlled simultaneously. It is suitable for milling very intricate products with shorter cycle times.

The Best Choice for Your Plastic Machining

At BKB Precision, we are ready to bring even the most complex designs to life with high-quality plastic machining. For the most challenging designs, we provide tailor-made solutions with advanced plastic machining. After receiving your technical drawing, we assess whether 5-axis milling, simultaneous 5-axis milling, another operation, or a combination of various techniques is most suitable for producing your desired product. Curious about all the possibilities? Don’t hesitate and contact us via the button below or explore our approach here.

Frequently asked questions about 5-axis milling

CNC milling involves the high-precision machining of plastic blocks or sheets. Simultaneous axis movements create precisely fitting geometries. At BKB, we also mill transparent, chemical-resistant, or heat-resistant high-quality plastics.

Production is ISO 9001 certified with documentation and traceability. Cleanroom processes are in place for sensitive sectors (e.g., medical technology). Find out everything about the standards we comply with and how we guarantee quality on our quality page.

At BKB, we machine standard plastics such as PMMA and PP, engineering plastics such as PETP and POM, and high-performance plastics such as PEI, PEEK, or PTFE and foam materials. Since the materials differ greatly from one another, for example in terms of their temperature resistance, stability, and hydrolysis resistance, the choice is tailored to your individual requirements.

We work with production tolerances of up to ±3 µm. This is possible thanks to our climate-controlled production environment, extremely accurate 5-axis machining centers, automated production processes, and the use of state-of-the-art measuring technology—all geared toward consistent precision, even in series production.

Additional machining steps include the assembly of (sub)assemblies, adhesive bonding with tailored adhesives (including UV) and welding processes such as infrared and hot gas welding. Individual adhesive techniques are also possible. Cleaning in accordance with phase 4 and processing under ISO class 7 conditions complete our range of services. We would be happy to advise you on the right processing steps.

Yes, medical and cleanroom requirements according to ISO Class 7 and ISO 13485, including packaging, are possible.