We work for, among others

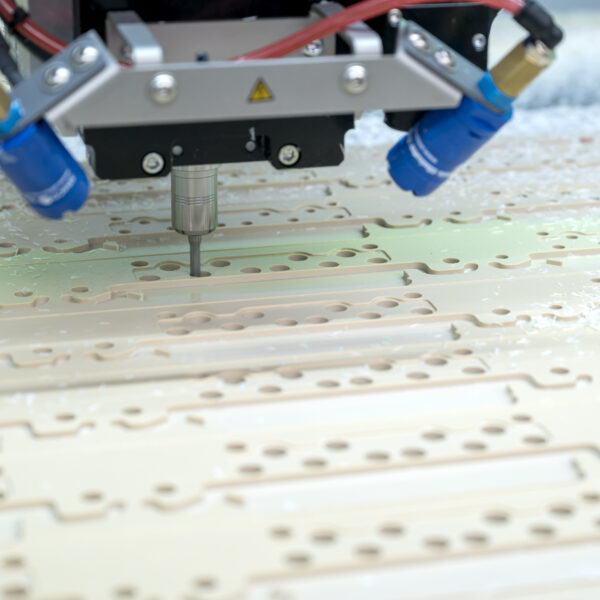

3-Axis CNC Milling of Plastic

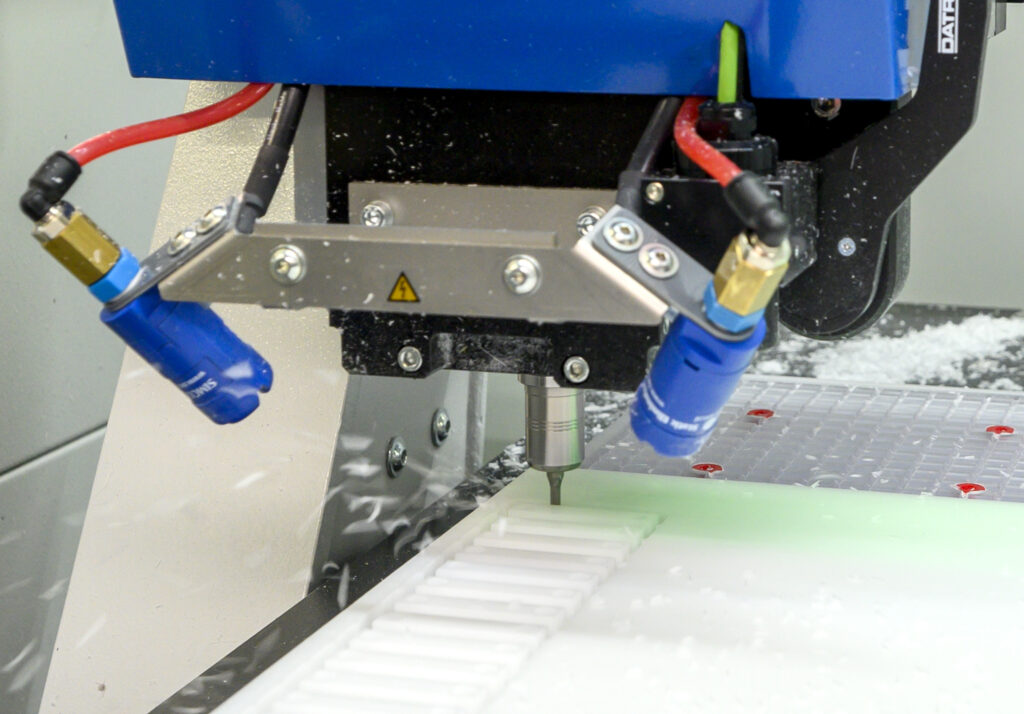

As the name suggests, a 3-axis mill allows the cutter to move in three directions: up and down, from right to left, and from front to back. The raw material is usually secured with vacuum or a clamp, allowing only the top of the product to be machined. We also employ this method in post-processing, especially when a specific side does not yet meet the drawing’s requirements.

What makes 3-axis milling unique is the precision it offers in producing components with complex geometries. Whether creating prototypes, manufacturing finished products, or performing precise post-processing, 3-axis CNC milling plays a crucial role in the production process of many plastic items. Feel free to contact us to discuss the possibilities and discover how we can contribute to realizing your specific needs and designs.

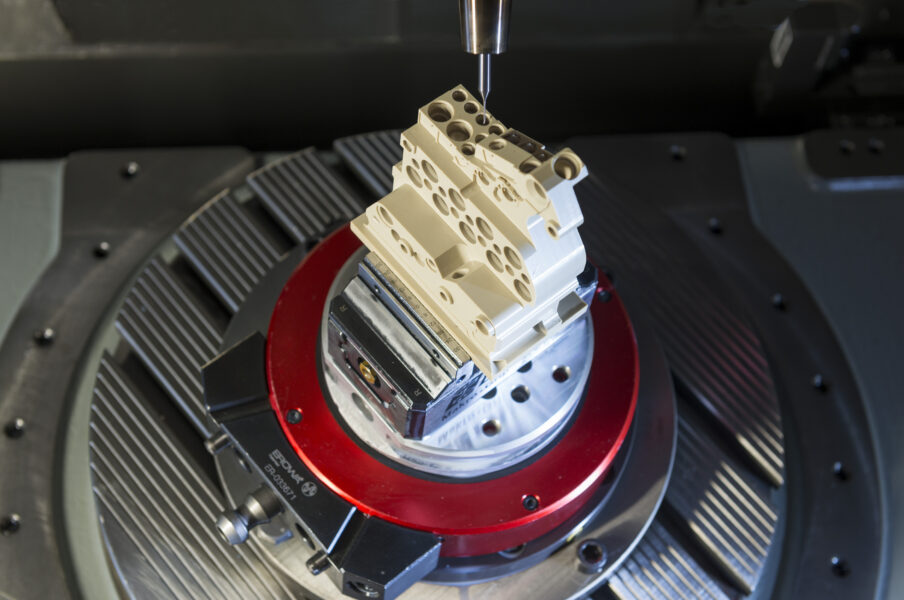

Our CNC Milling Machines for 3-Axis Milling

We possess various CNC milling machines, each with unique features. These machines are all meticulously maintained to ensure optimal precision and efficiency when machining plastic components. Our commitment to quality is evident in the fact that all these operations take place in a conditioned hall, preventing temperature fluctuations from affecting the material or the end product.

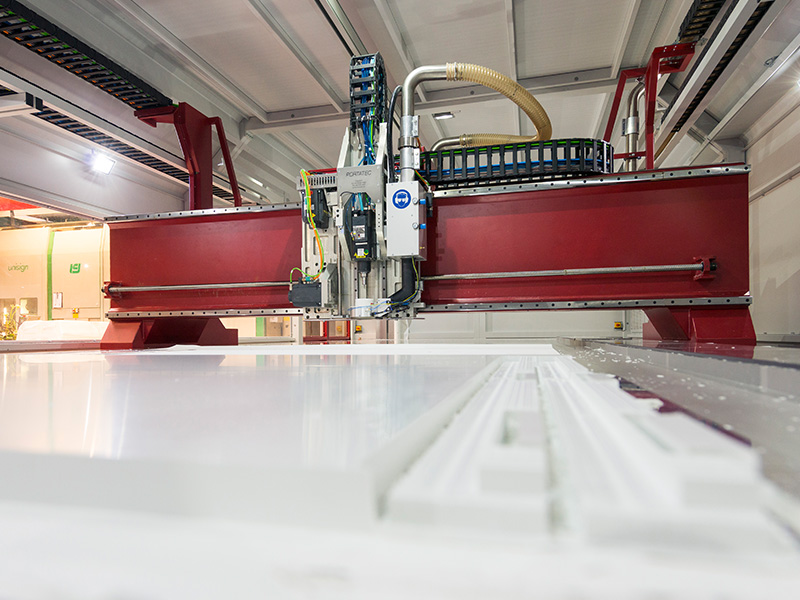

For processing large plastic sheets, we utilize our gantry milling machines. With these advanced machines, we can also guarantee quality on a large scale. Curious about all our 3-axis, 5-axis, and gantry milling machines? Discover them through the button below.

The Specialist in Delivering Precision and Quality in Your Milling Work

With over 40 years of experience, we emphasize craftsmanship and have evolved into specialists in delivering precision and quality in plastic components. No challenge is too big for us, and that’s why we continually strive to push the boundaries in plastic machining. This extends beyond just our 3-axis CNC milling machines, as our advanced machinery consistently ensures that each product meets exact specifications. Curious about all possibilities? Feel free to contact us!

Frequently asked questions about 3-axis milling

CNC milling involves the high-precision machining of plastic blocks or sheets. Simultaneous axis movements create precisely fitting geometries. At BKB, we also mill transparent, chemical-resistant, or heat-resistant high-quality plastics.

Production is ISO 9001 certified with documentation and traceability. Cleanroom processes are in place for sensitive sectors (e.g., medical technology). Find out everything about the standards we comply with and how we guarantee quality on our quality page.

At BKB, we machine standard plastics such as PMMA and PP, engineering plastics such as PETP and POM, and high-performance plastics such as PEI, PEEK, or PTFE and foam materials. Since the materials differ greatly from one another, for example in terms of their temperature resistance, stability, and hydrolysis resistance, the choice is tailored to your individual requirements.

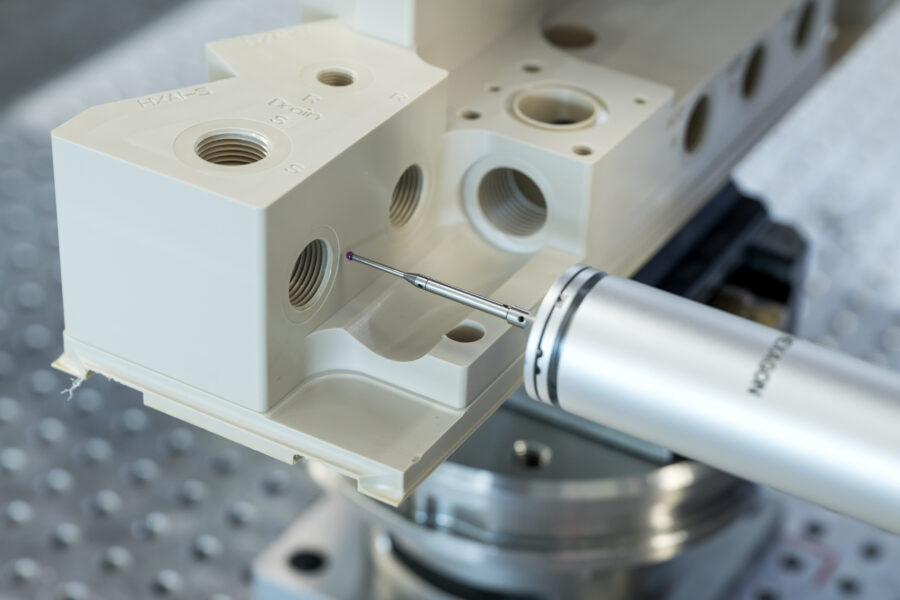

We work with production tolerances of up to ±3 µm. This is possible thanks to our climate-controlled production environment, extremely accurate 5-axis machining centers, automated production processes, and the use of state-of-the-art measuring technology—all geared toward consistent precision, even in series production.

Additional machining steps include the assembly of (sub)assemblies, adhesive bonding with tailored adhesives (including UV) and welding processes such as infrared and hot gas welding. Individual adhesive techniques are also possible. Cleaning in accordance with phase 4 and processing under ISO class 7 conditions complete our range of services. We would be happy to advise you on the right processing steps.

Yes, medical and cleanroom requirements according to ISO Class 7 and ISO 13485, including packaging, are possible.