We work for, among others

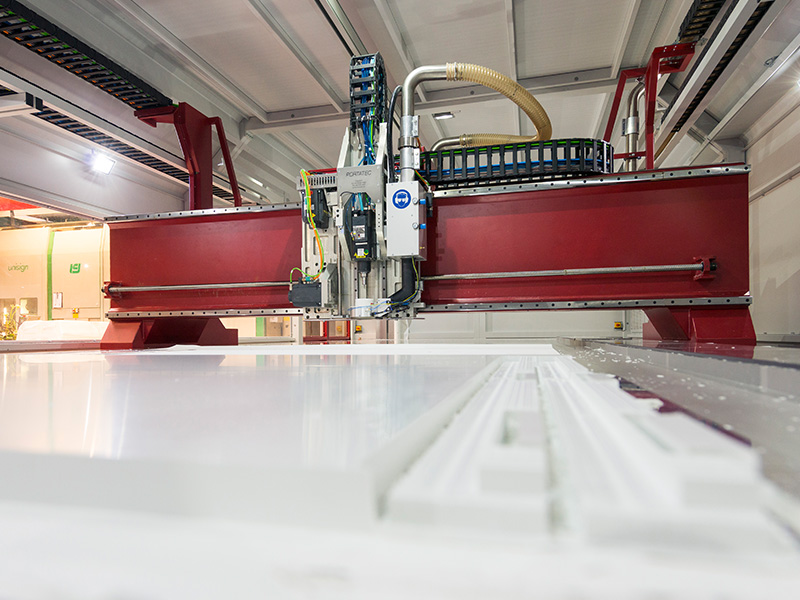

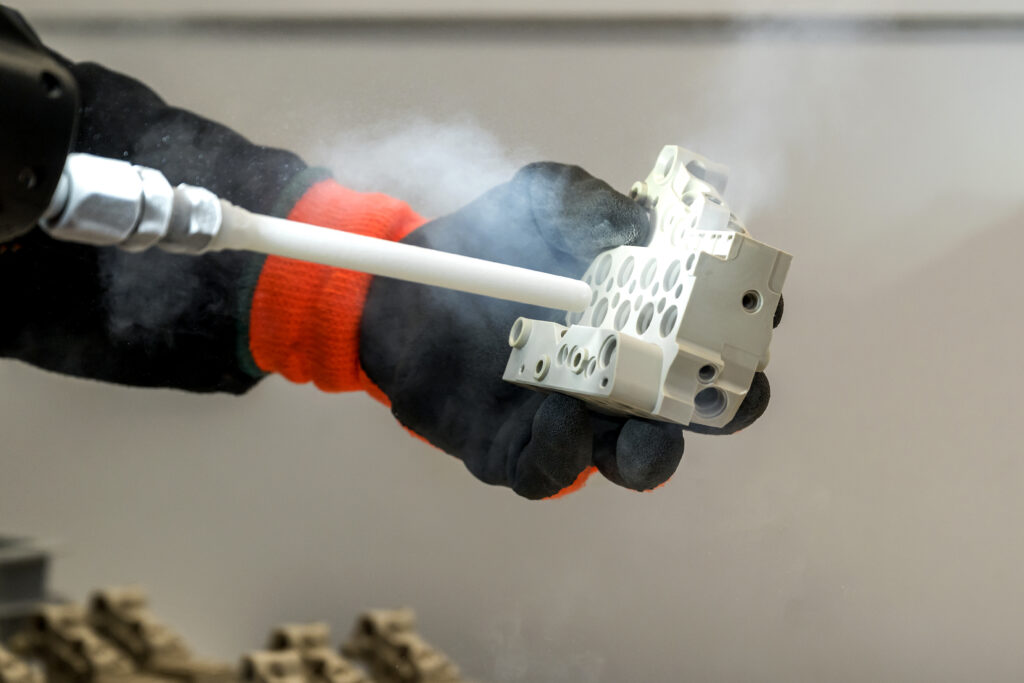

Deburring with the Cold Jet dry-ice cleaning machine

Cleaning processes within BKB were recently expanded by the addition of Cold Jet machines. These dry ice cleaning machines are user-friendly, compact, and specially developed for cleaning and deburring delicate surfaces, complex parts, and small openings.

Initially, the Cold Jet technique was only used within the metal industry. However, BKB Precision has successfully made the process available for the finishing of customer-specific plastic products and components.

Curious about how we deburr using the Cold Jet machine? You can watch the video with the button below.

MicroParticle technology

BKB Precision has chosen to use Cold Jet’s patented MicroParticle technology. This allows products to be accurately and neatly deburred and cleaned without damaging the material. Deburring with dry ice is also environmentally friendly and cost effective.

Director Mannes Westhuis: ‘We are very happy with how this machine has been integrated into our production process, given the quality of the results and the time that it saves. Using these machines significantly reduces the chance that components will still have burrs after the cleaning process’

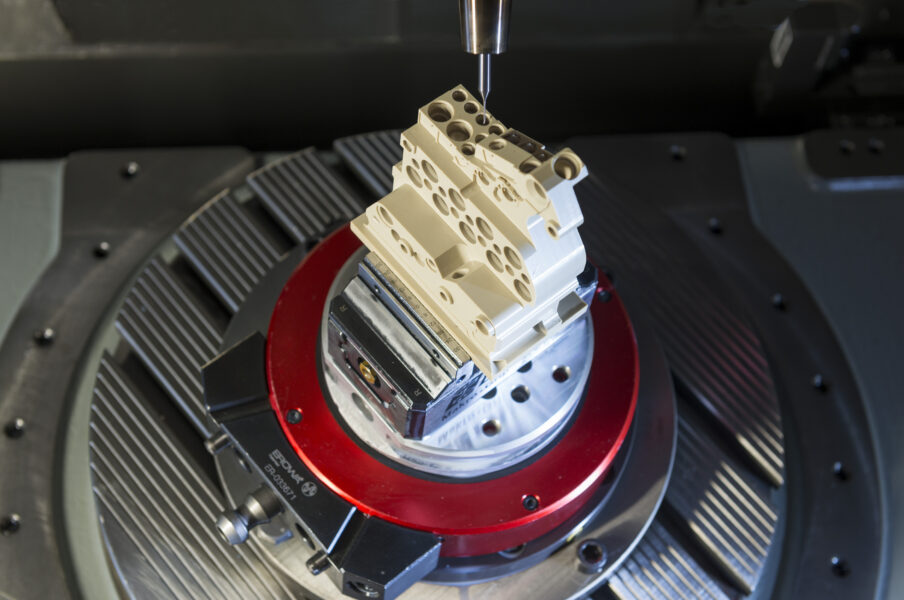

Ultrasonic modular cleaning system

We also have a modular cleaning system, through which products are cleaned in accordance with the ISO class 7 cleaning standard. Afterwards, the cleaned components are usually reassembled in our clean room and sent to our customers, who incorporate them into high-tech applications.

We use the modular system from FinnSonic Genius. This system combines an optimal cleaning result with a flexible layout on limited floor space and complies with all applicable health, safety and environmental standards. Being able to clean products ourselves often shortens lead times, which means we offer more added value.

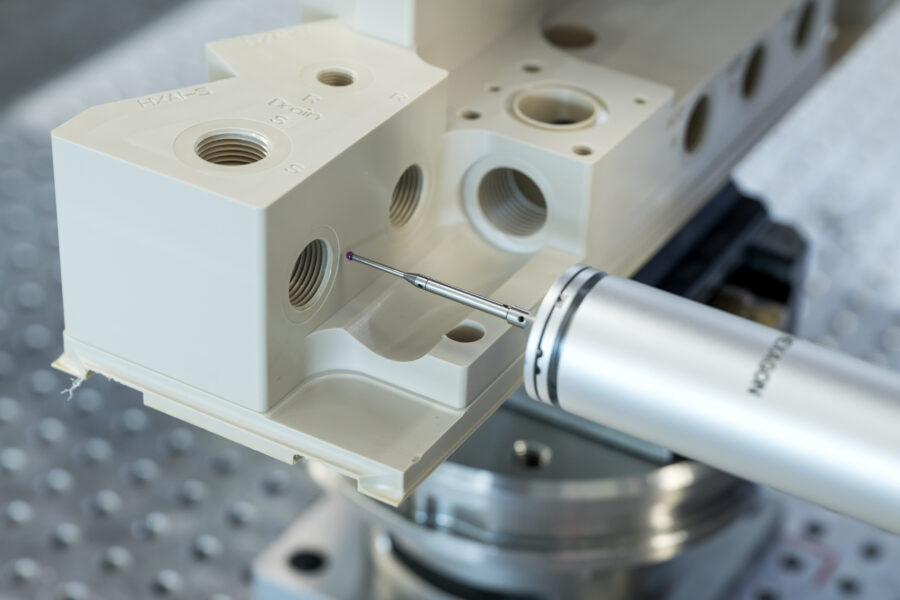

Microscopy

At BKB Precision, we use various microscopes during the precision cleaning and deburring of plastic components and products. A good example of this is the stereo viewer system Mantis® from Vision. This microscope offers clear 3D magnification and excellent optical performance.

This is ideal when inspecting machined plastic parts in detail and finishing them with precision. With this microscope, we can also use special conversion lenses for an extra magnification. This allows us to make even better assessments of components and products.

Frequently asked questions about plastic cleaning

In the cleanroom, we mainly package high-precision plastic parts from CNC machining that are used in sensitive high-tech applications. These include components for the semiconductor, medical technology, and optical industries. The parts are thoroughly cleaned and inspected beforehand and packaged under ISO-certified conditions with low particle content.

A cleanroom must comply with defined particle concentrations in accordance with ISO 14644. BKB Precision cleans and assembles plastic components in ISO class 7 cleanrooms. Strict requirements apply to air purity, temperature, air flow, and staff behavior in order to guarantee the highest product quality and process safety for sensitive applications.

Cleaning involves various coordinated processes, including dry ice blasting with Cold Jet technology, ultrasonic cleaning, and manual finishing under a microscope. The aim is to completely remove residues such as burrs, particles, or lubricants. Depending on the requirements, cleaning is carried out to ISO class 7 in the cleanroom—including inspection and packaging.