Our working method

Our working method

At BKB Precision, we strive for success through collaboration within the chain for improved processes and innovative ways of working. We facilitate clients in rethinking designs and think with them about the possibilities in plastics. With our extensive experience and expertise, our work process is fully geared to the needs of the client.

From wish to realisation

At BKB Precision, we process high-quality plastics for the high-tech industry. Our goal is efficient production of critical parts at attractive cost and delivery time. For many clients, there is still much that is unknown in the field of plastic machined products.

We therefore consider it important to be able to advise the customer well and, above all, in a timely manner. At each step in the process, you will have direct contact with a specialist. Thanks to our working method, we ensure that the customer’s wishes are ultimately realized.

1. Contact us

Once initial contact has been made and there appears to be a match between BKB Precision and the client, we would appreciate receiving the assignment in our rfq@bkbprecision.com mailbox.

2. Calculation

After receiving the order, our colleagues will get to work on the calculation. This way, the customer will have a clear idea of what the requested product will cost.

3. Registration

Once you have agreed to the price calculation, we will send you an order confirmation. You will then be assigned a contact person and your order will be scheduled.

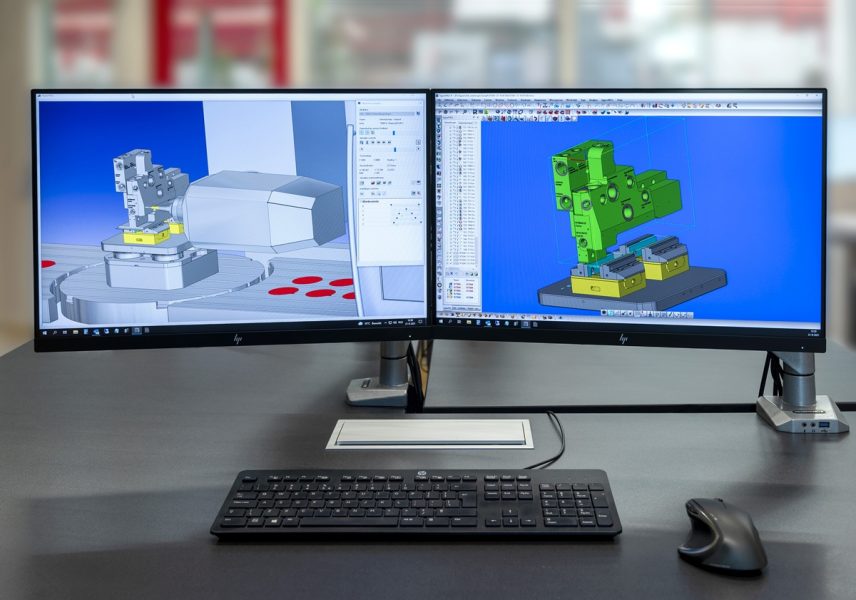

4. Programming

Our CAD-CAM program is used to program the machining operations and send them to our machining centers.

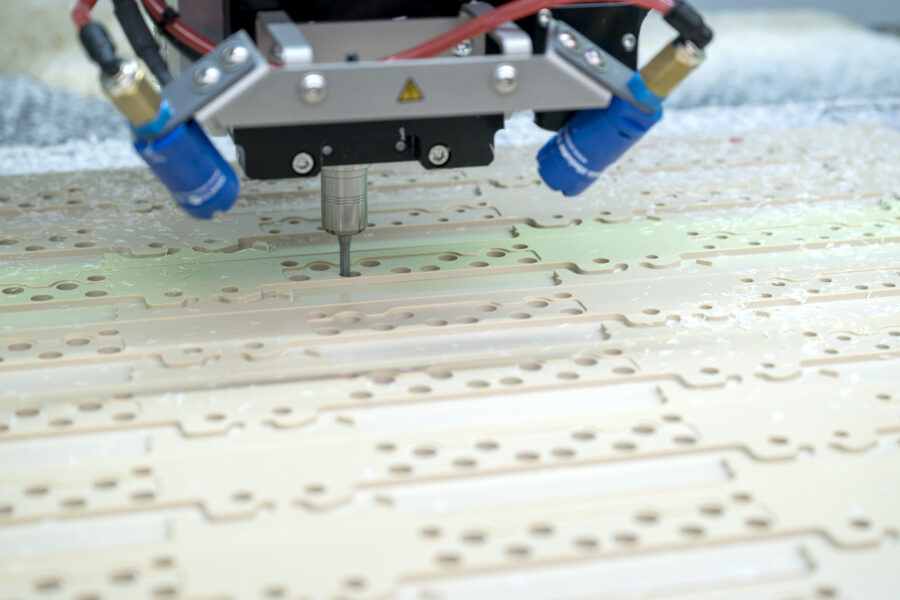

5. Production

Your product is manufactured using one of our modern CNC-controlled machines, after which it may sometimes require further finishing using various processing techniques.

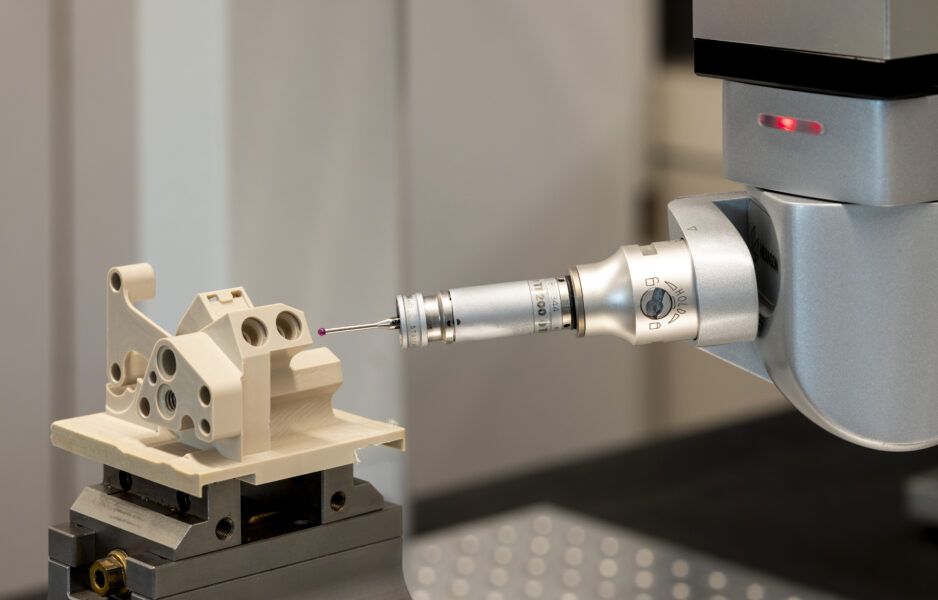

6. Inspection

The Quality department checks whether the products meet the specifications during the production process and before the products are sent to the Logistics department for shipment. Upon request, we provide certificates and measurement reports for the delivered products.

7. Distribution

The items are carefully packaged and, at the customer’s request, we can follow strict packaging requirements. After packaging, the products are delivered to the customer by a jointly selected supplier.

Innovation and improvement

As the leading plastics machining company in the Netherlands, we are constantly innovating and improving the manufacturing process and participating in challenging, innovative projects of our clients. One of our most recent projects is a fine example of this. In collaboration with the customer and suppliers, we took on a new challenge to reprocess a 3D-printed PEEK product, which involved several challenges to overcome.

The cost of a product

The cost of a given product consists of a number of different sectors, including setup time, machine time and material costs. A custom price can be calculated based on these three sectors. Do you have more questions about how we work, payment terms or other aspects? Get in touch!

Sustainability within BKB Precision

Corporate social responsibility is an important principle for BKB Precision. We are aware of our impact on the natural environment and continually engage with various efforts and initiatives. We also continue to look for ways in which we can invest in a better future. Read all about it in our sustainability report.