From idea to realisation

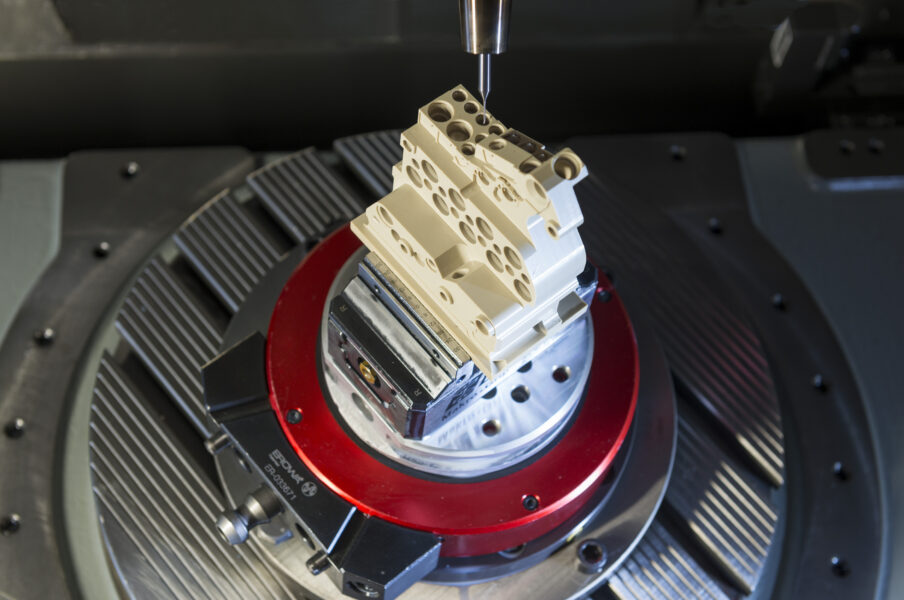

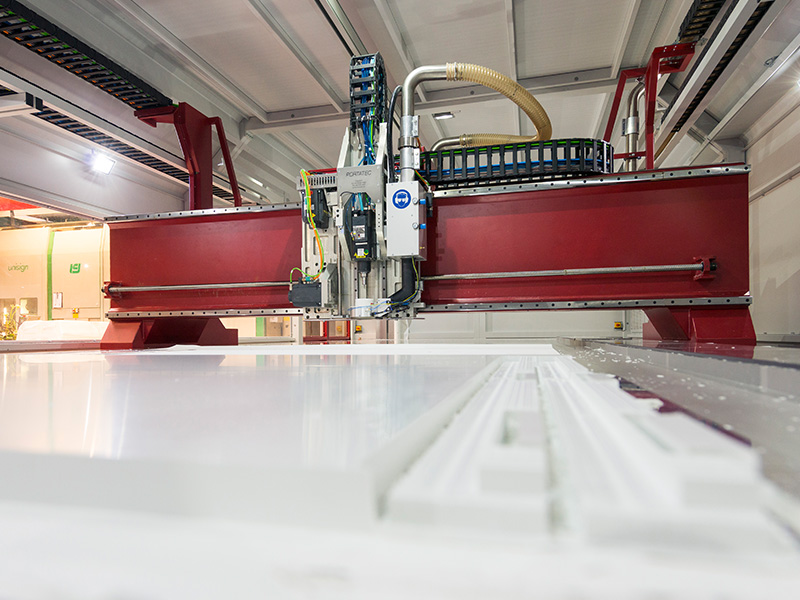

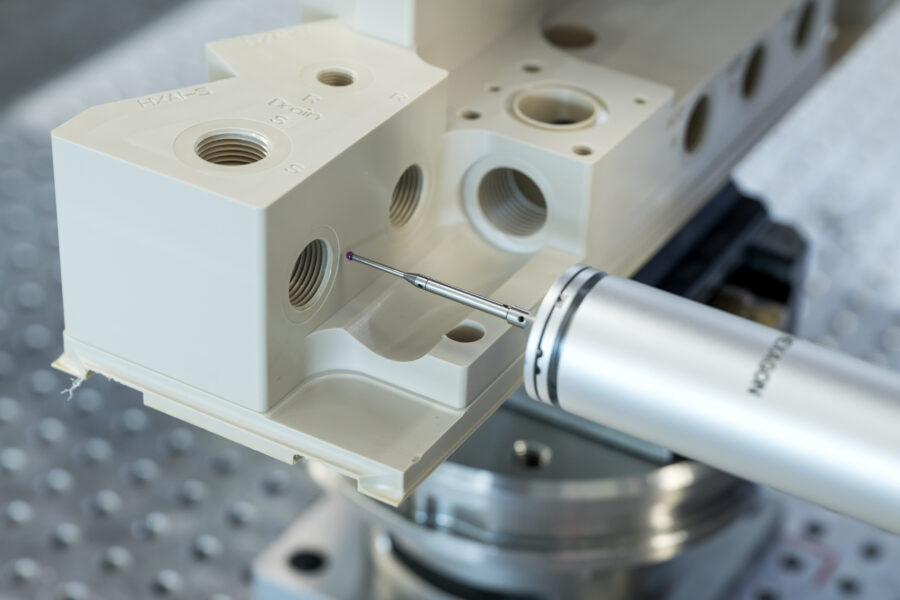

At BKB Precision, we process high-quality plastics for the high-tech industry. This includes sectors such as the semiconductor industry, medical industry, defence and aerospace, etc. These markets are mainly focused on so-called high-performance plastics, but we frequently work with a variety of engineering plastics.

Sam Versteeg, Business Development: ‘The modern customer relationship combines operational excellence with customer intimacy. This is perfectly consistent with our vision here at BKB Precision. We deliver added value and always think with the customer. They are free to contact us with whatever questions they have, from Design to Manufacture, and we are always delighted to seize the challenge of coming up with an effective approach to Product Design together.

‘We have noticed that companies are increasingly looking for a good sparring partner. There is a lot which people don’t know about processed plastic products and their specific properties. That is why it is important to be properly advised by a specialist and – also important – to get that advice early enough in the process. By addressing this in the preliminary phase, you can ultimately ensure the realisation of the right product at the desired cost and delivery date.’

Partnership and manufacturability

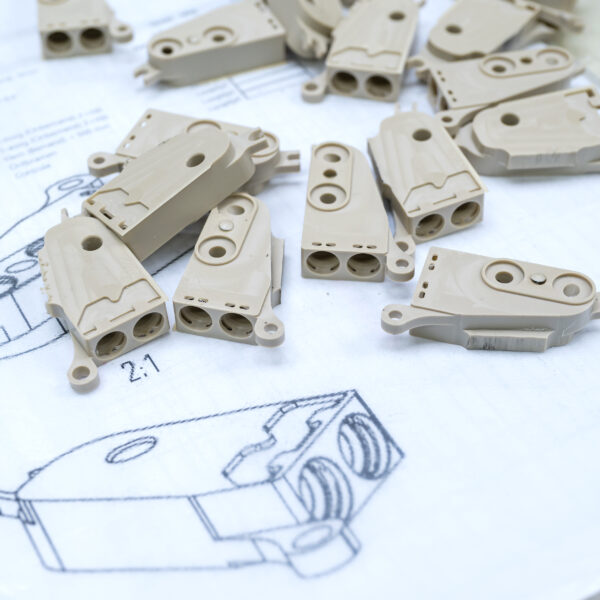

‘(Potential) customers appreciate that we think with them when it comes to the design and are open to advice about materials. If they want, we can even make a prototype. It is always a challenge to find the right balance between innovation, manufacturability and costs, but with the support of our Business Development department, this often leads to designs which are both functional and cost-effective. We can then put them into production.

‘That’s why partnership and having a long-term relationship are important factors for BKB Precision. They work well for the development of the product, but also for such things as market development and chain integration.’