Cleanroom cleaning ISO Klasse 7

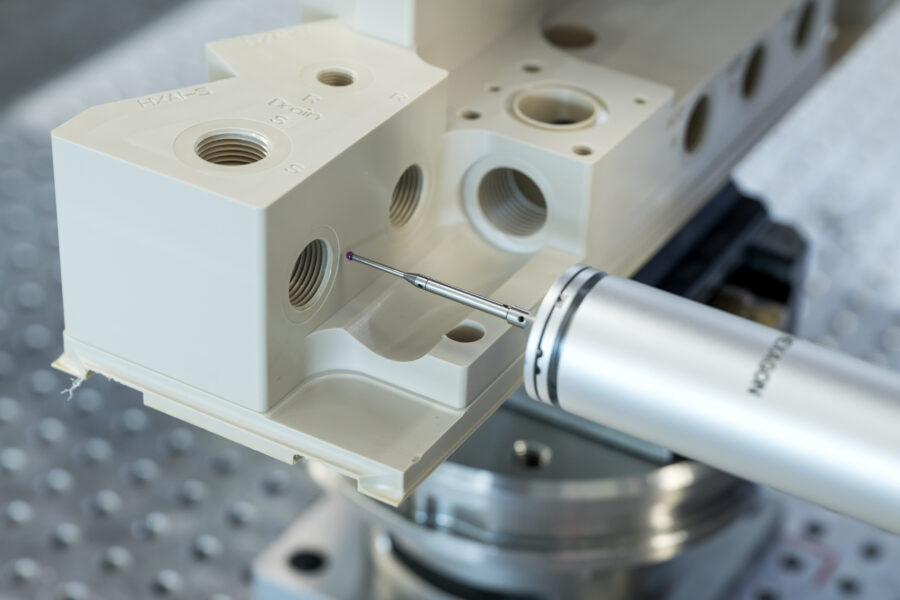

The cleaning of components and products is done extremely carefully and we work according to a strict protocol. Plastic products are cleaned in our cleaning room to the Grade 4 (ISO class 7) standard – and we can clean to a higher class if necessary. This means we can also meet the strict requirements of the aerospace, semiconductor and medical industries.

Cleanroom assembly

The semiconductor industry and medical industry are increasingly using composite manifolds. On request, we can assemble your products in accordance with cleanroom standards. You supply the specifications and our specialists in the Assembly department will assemble your manifold(s).

Cleanroom packaging

The packaging of your plastic products in our clean room is done to ISO class 7 standard. In fact, cleanroom packaging is our everyday work and cleanroom specifications are strictly observed as standard.