2019 | Industrial use of high-quality plastics in 2020: What can we expect?

High-quality technical plastics are increasingly used in a variety of industries, from machine building to aviation technology. This is partly due to its high durability, low unit weight and resistance to external factors. At the same time, technological developments in the field of machining techniques are moving incredibly fast.

In this article, we look ahead to what 2020 will bring us and how plastic can contribute to a productive and sustainable future.

Innovative applications thanks to technical plastics

High-quality technical plastics play an important role in innovative applications. Think of modern knee or hip prostheses which last a lifetime thanks to wear-resistant plastic parts or the use of high-performance plastics in aircraft, making them lighter, more economical and environmentally friendly.

There are numerous innovations in different industries which could not have been achieved without high-quality or high-performance plastics. Innovations which, in addition, happen very fast. Technical universities are currently conducting research into self-healing polyurethane elastomers, smart composite materials and coatings, and nano-structured polymers. These are all plastics which will have a huge impact on industrial applications in the near future.

BKB Precision also follows these trends and tries to translate them into solutions for our clients.

Lightweight plastics

In 2020, we will also see an increasing demand for lightweight plastics. Lightweight plastics offer engineers and designers the opportunity to improve the design and efficiency of products.

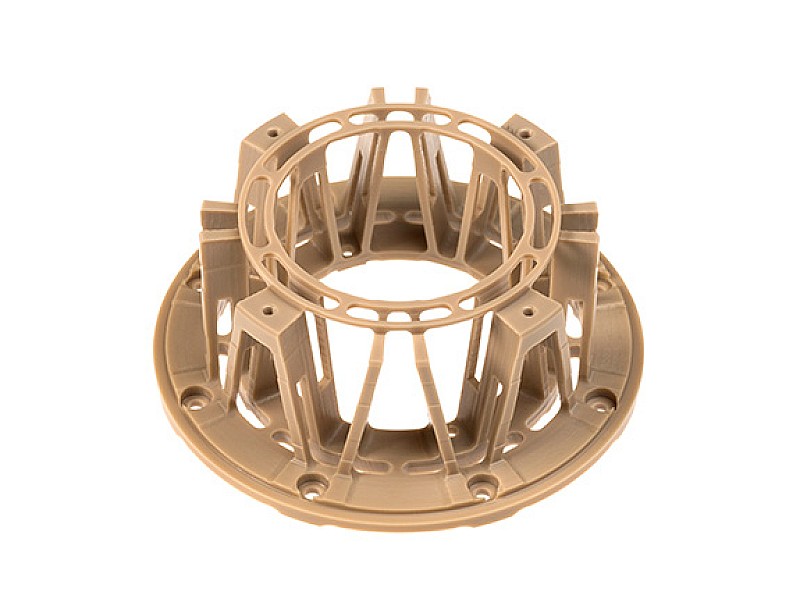

Large industries such as aviation, the automotive industry and mechanical engineering are switching from metal parts to plastic parts. High performance plastics, such as PEEK or PEI, are especially utilised for this.

The advantage of these plastics over steel include a lower unit weight, which means that highly dynamic systems can perform even better. In addition, the lower weight means that less energy is needed to move the end product – a lighter aircraft, for example, uses less fuel.

That’s why BKB Precision also produces more parts for the Aerospace Industry. And we are happy to share our expertise on the possibilities.

Plastics industry 4.0

The fourth phase of the industrial revolution is also sometimes called Smart Industry or Industry 4.0. Thanks to the Internet of Things, machines in factories are connected to each other, as well as being connected to smart dashboards and maintenance systems. Within these intelligent factories, large amounts of data are collected, analysed and processed, so that processes can be optimised with smart information.

This creates new opportunities in the value chain, because lead times can be shortened and work done more efficiently. BKB Precision’s fully automated machining centres are a good example of this. CNC maching, turning and milling can be done very accurately thanks to high-tech milling machines and robotization – and it can be done 24/7. This offers more flexibility in production and assembly. Robots are also getting smarter, and the first robots to use self-learning algorithms are already being tested.

BKB Precision has also made use of a variety of robots for a long time. In 2020, further robotization will certainly play a role within the company.

Want to know more about high-quality plastics?

Do you want to experience for yourself the future of high-quality plastics for industrial use? We would be happy to welcome you here, so you can get to see the many possibilities available in the field of plastic processing. Whether it’s about CNC milling and turning, moulding or (cleanroom) assembly, BKB Precision is your partner in plastic processing. Please contact us for more information.